Studio 5000 vs Connected Components Workbench. Choosing the Right Rockwell Automation Software

Learning PLCs? Don’t waste your money—choose the right software from the start.

When working with Rockwell Automation products, choosing the right development environment can significantly impact the success, efficiency, and cost-effectiveness of your automation projects. Two popular software packages in the Rockwell ecosystem—Studio 5000 and Connected Components Workbench (CCW)—serve distinct purposes and audiences.

One of the most common questions I get is “I want to purchase one you your PLC trainers for Studio 5000, which license of Studio 5000 should I purchase”. My next question always is do you need to learn Studio 5000 or do you just want to learn Studio 5000.

What I find is that question puts people into two basic groups.

Those who are working with the Controllogix/Compactlogix PLC and truly do need a PLC trainer that they can learn Studio 5000.

Those who are looking to get into the industry and Allen Bradley is the most popular PLC in the area.

If you are in group #1 then Studio 5000 and a Compactlogix PLC is the right fit for you. If you are in group #2 then I usually recommend Connected Components Workbench and the Micro800 PLC. Below are details on each one.

Overview of Studio 5000 Logix Designer

Studio 5000 is Rockwell Automation’s flagship development suite for advanced industrial automation systems. Designed to support the Logix 5000 family of controllers, such as the CompactLogix and ControlLogix platforms, Studio 5000 integrates a broad range of tools to enable full lifecycle project management.

Key Features:

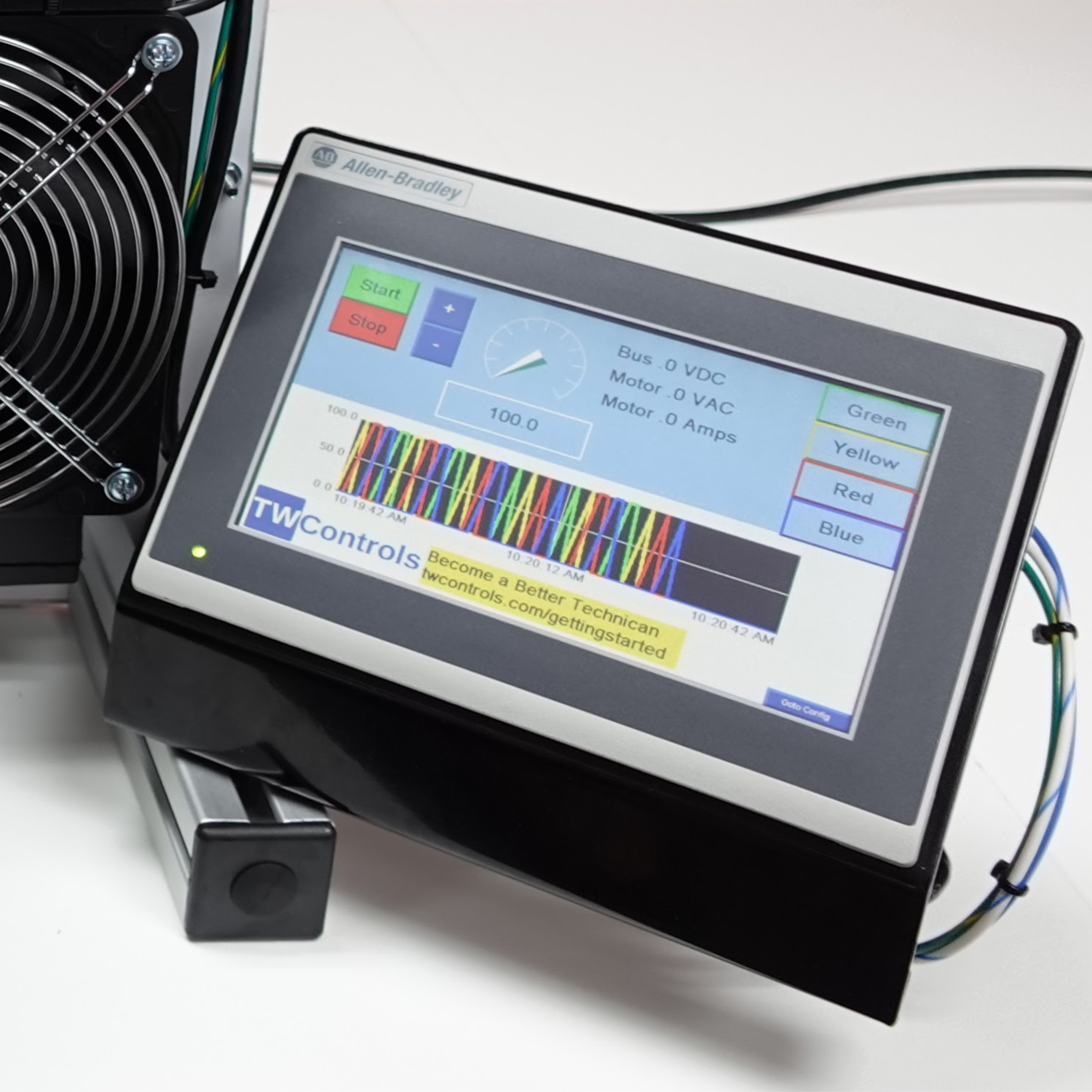

Multidisciplinary Environment: Includes modules like Logix Designer, View Designer, and Application Code Manager.

Support for Advanced Programming Languages: Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), and Sequential Function Chart (SFC).

Robust Hardware Compatibility: Compatible with ControlLogix, CompactLogix, Kinetix drives, POINT I/O, and a variety of third-party devices.

Comprehensive Networking Support: Seamless integration with EtherNet/IP, DeviceNet, and ControlNet.

Safety & Motion Control: Built-in tools for integrated safety and motion programming.

Target Audience:

Studio 5000 is ideal for large-scale automation systems where high complexity, extensive I/O, and advanced motion or safety control are required. Typical users include system integrators, OEMs, and industrial automation engineers working in sectors such as manufacturing, oil and gas, water treatment, and pharmaceuticals.

Overview of Connected Components Workbench (CCW)

Connected Components Workbench (CCW) is a more lightweight and streamlined software package that caters to simpler applications, particularly those using Micro800 series controllers. It consolidates programming, configuration, and visualization tools into a single user interface.

Key Features:

Simplified Programming Interface: Supports Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST).

Preconfigured Templates and Wizards: Speeds up development time.

Micro800 Controller Integration: Designed primarily for small standalone machines.

Basic HMI Integration: Compatible with PanelView 800 HMIs.

Device Configuration: Allows easy setup of PowerFlex drives and other components.

Target Audience:

CCW is best suited for smaller applications such as standalone machines or basic automation tasks. It is widely used by OEMs, panel builders, and machine builders who prioritize cost-efficiency and ease of use over complexity.

Comparison

Cost Analysis

Studio 5000: Requires a paid license that ranges from $500 to several thousand dollars a year, depending on the version and modules selected. The hardware it supports.

CCW: Free to download and use, making it ideal for budget-conscious projects. It pairs with the more economical Micro800 hardware line, reducing overall project costs.

While Studio 5000 has a higher up-front cost, it provides scalability and features that may reduce engineering hours in large projects. CCW delivers significant cost savings but may be limited in long-term flexibility.

Ease of Use

Studio 5000: Has a steeper learning curve due to its extensive features and modular design. Requires more experience or training to use effectively.

CCW: User-friendly and designed with simplicity in mind. Ideal for those new to PLC programming or working on quick deployments.

If your team includes experienced engineers, Studio 5000’s complexity is justified. For beginners or quick-turnaround jobs, CCW is easier to learn and deploy.

Scalability

Studio 5000: Highly scalable, supporting projects ranging from small machine controls to entire plant-wide systems. It can handle thousands of I/O points and sophisticated networking.

CCW: Limited scalability; best used for applications with lower I/O requirements and minimal complexity.

Studio 5000 is better suited for systems that may expand over time, while CCW works best for static, compact installations.

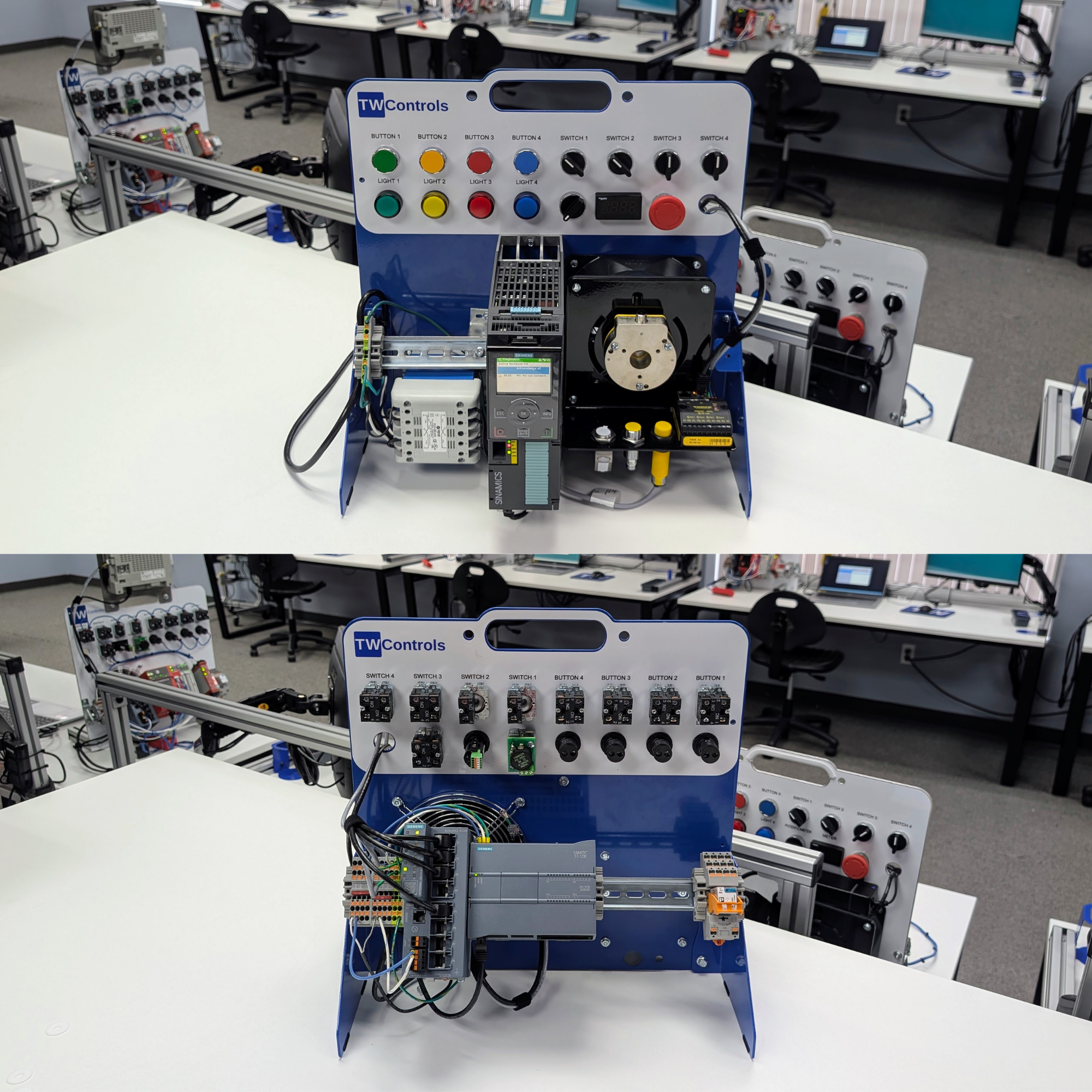

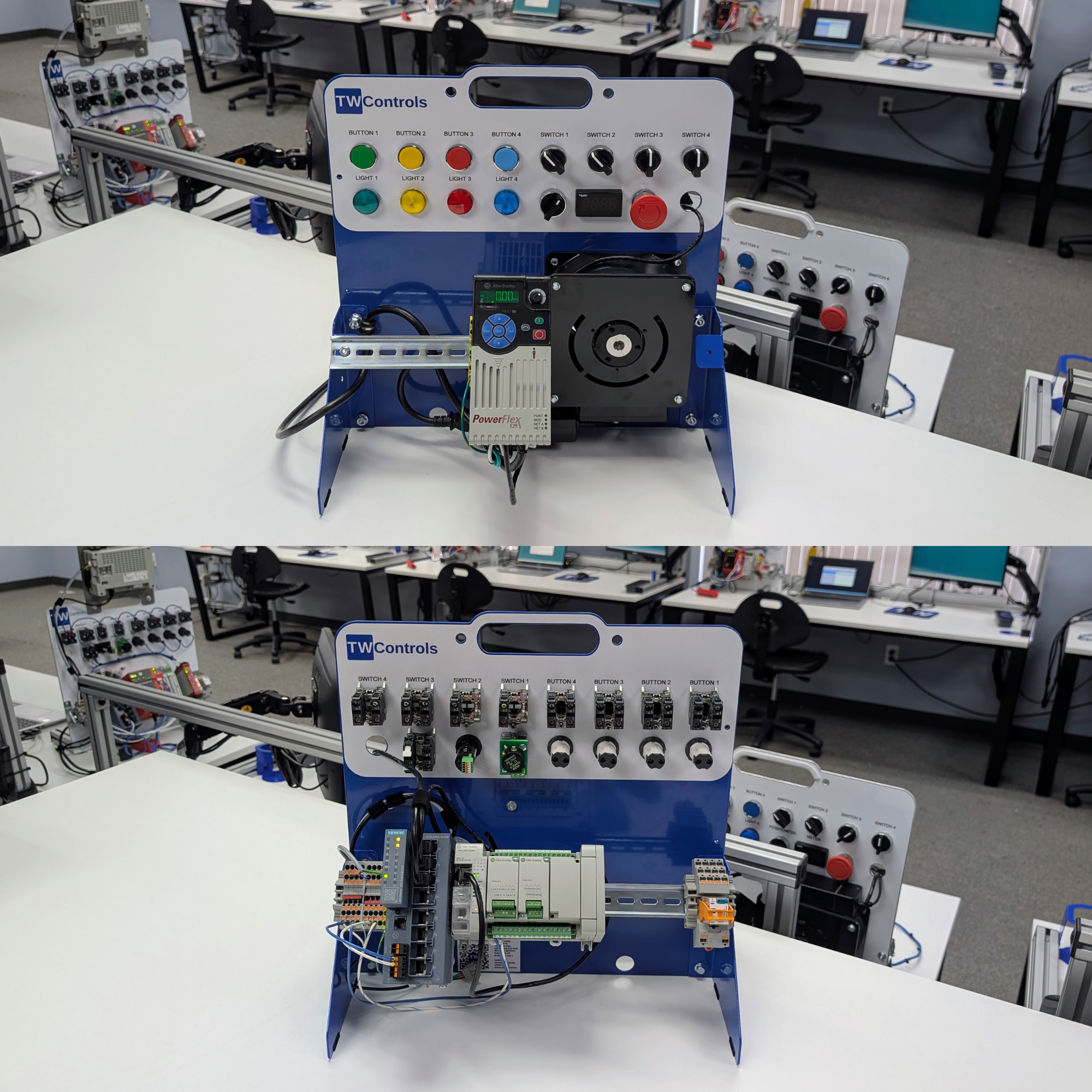

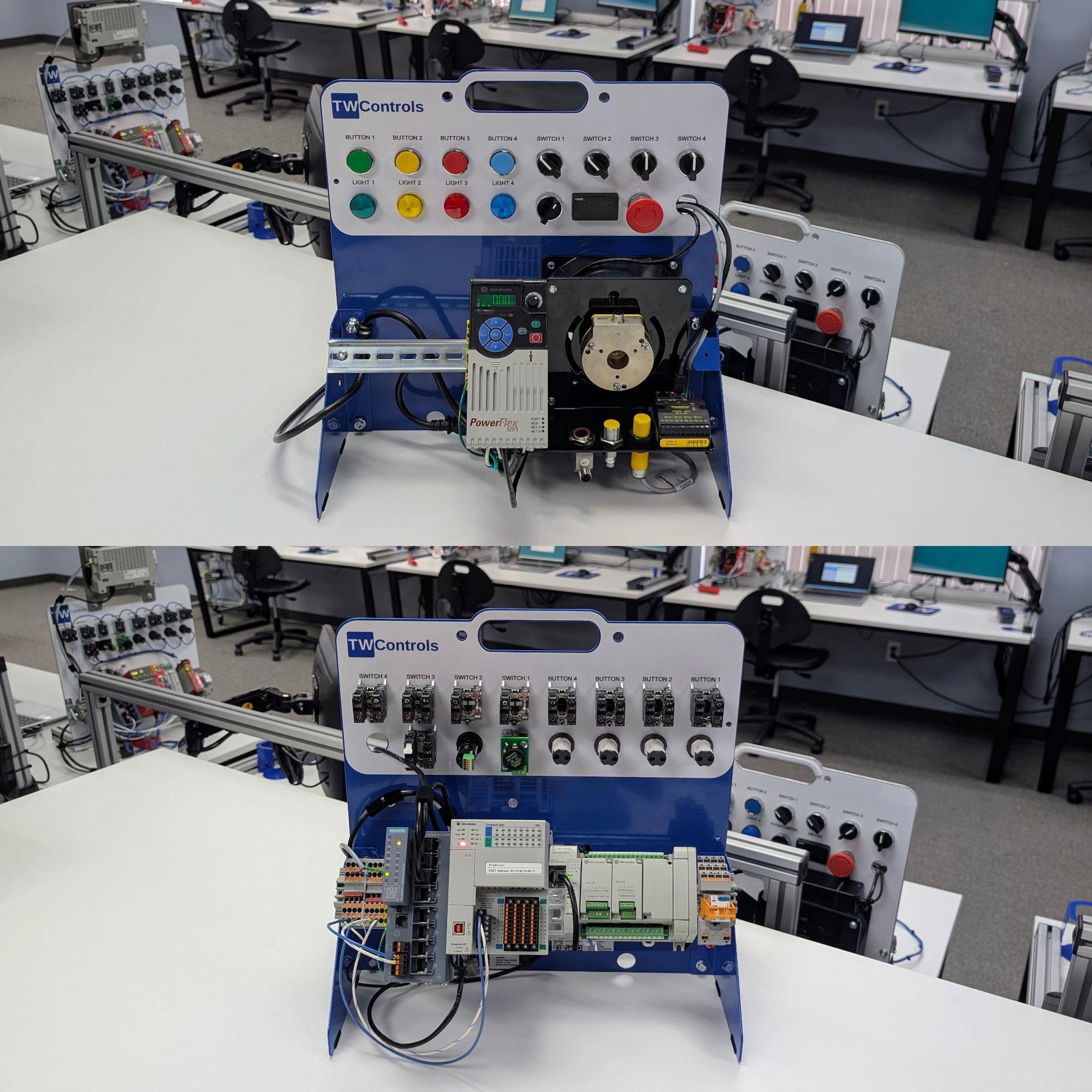

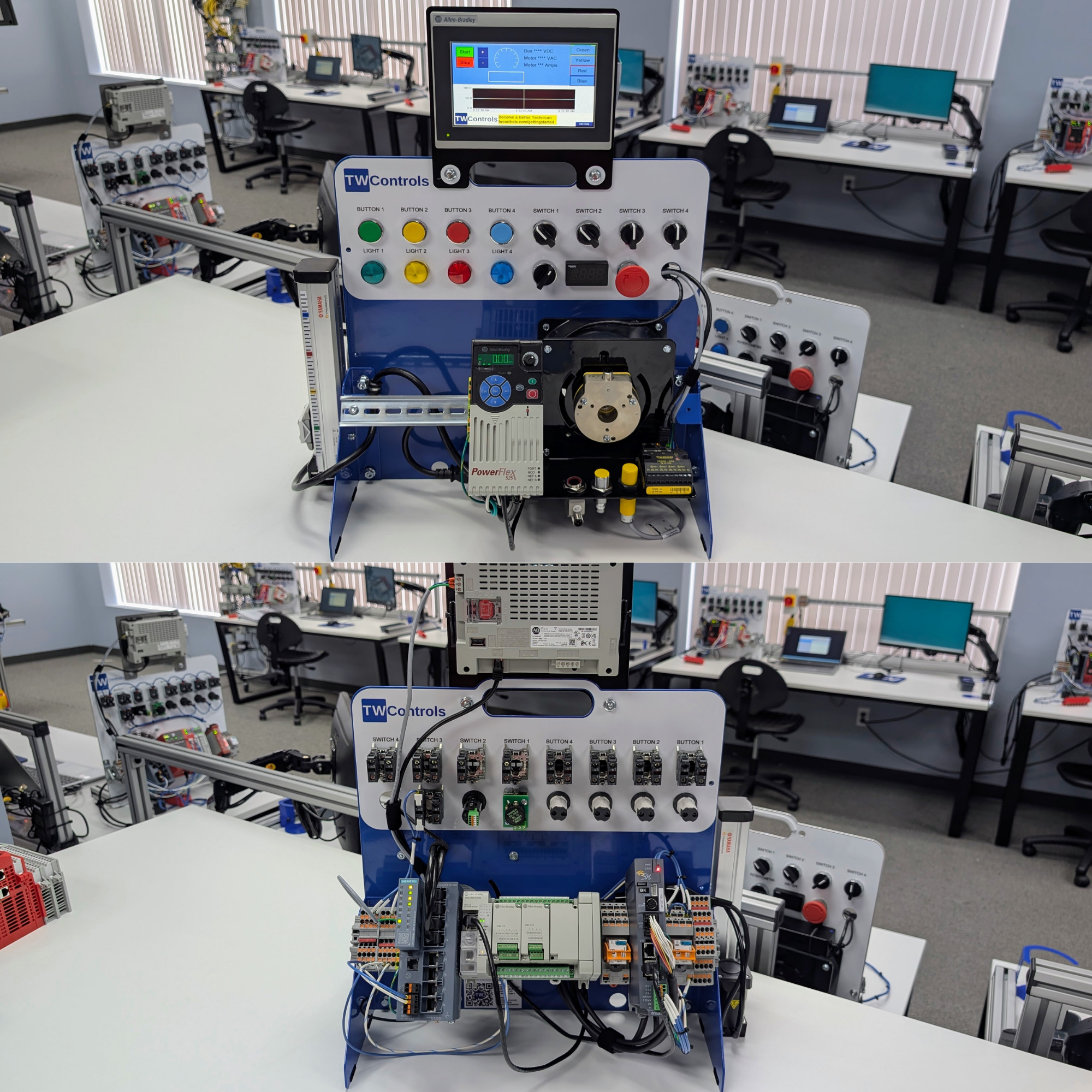

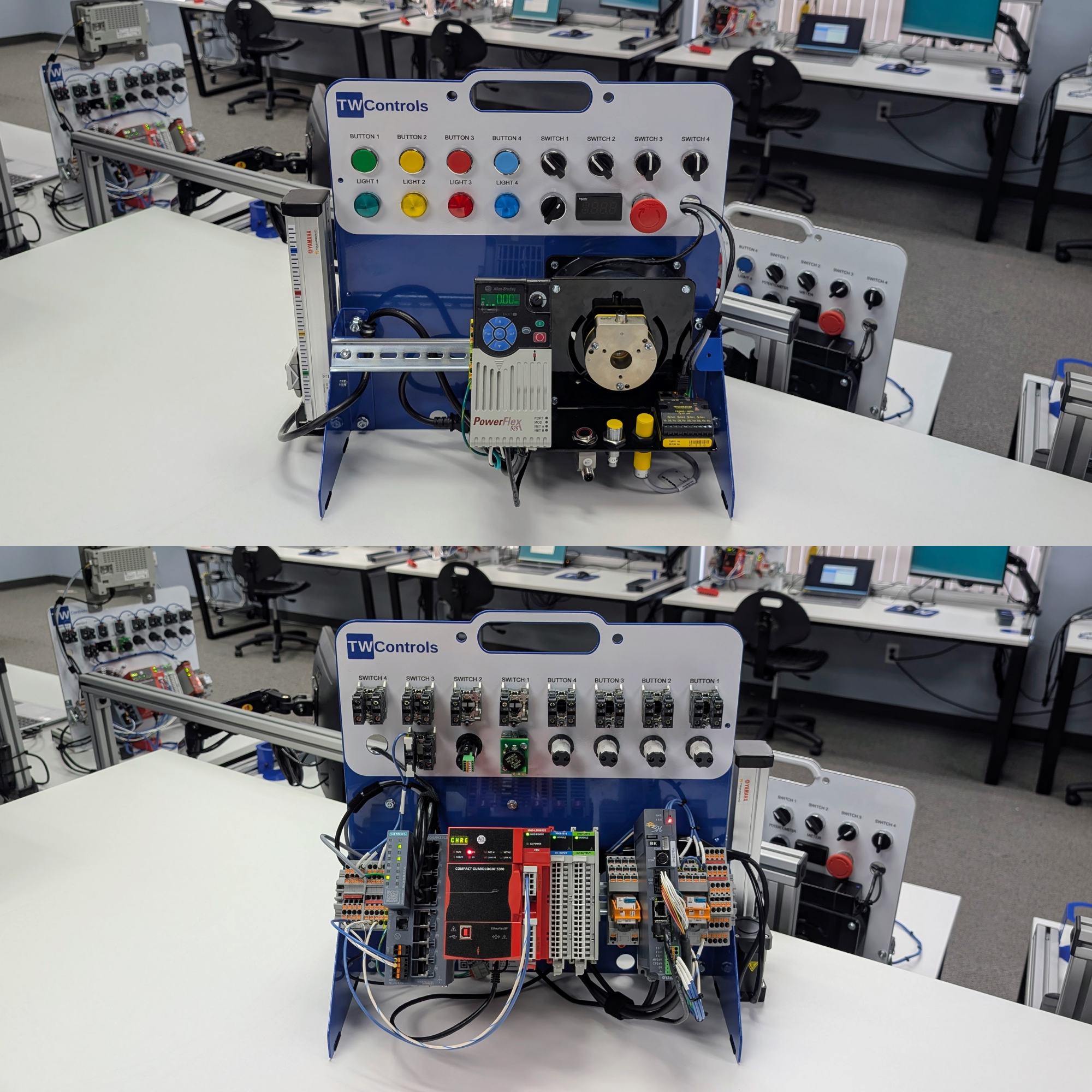

Customize your PLC Trainer by selecting the brand that you wish to learn and what options you need to accomplish your goals.