SCADA / HMI Design Training

This training is designed for individuals seeking to expand their knowledge in SCADA / HMI design, with a focus on using Inductive Automation's Ignition, a leading solution in the industry.

CLASS: SCADA-101 - HMI / SCADA Training with Ignition

LENGTH OF TIME: 2 Days

LOCATION: Roanoke, VA

COST: $2,000 per person

A Project-Based Approach to Control Systems

In the world of industrial automation, a common challenge is translating a client's needs from a detailed project scope into a working system. This workshop tackles that challenge head-on by providing a unique learning experience based on a real-world scenario. Instead of just teaching theoretical concepts, you will have to build out a SCADA system based on a physical machine in the classroom including tank levels, pumps, mixers, robot, and vision.

This isn't a simple simulation; it's a deep dive into the practical application of integration principles. You will learn to navigate the complexities of a real-world project, including:

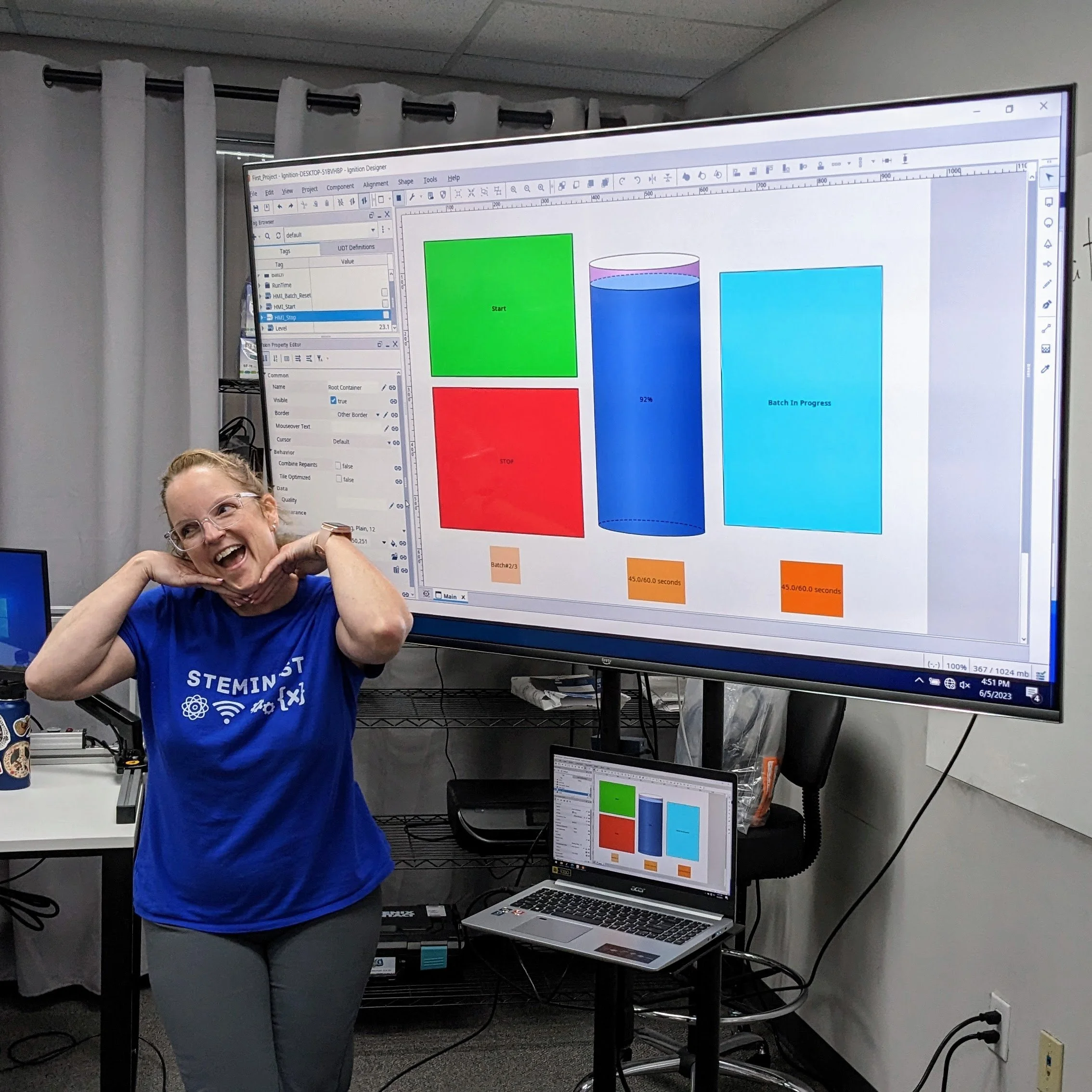

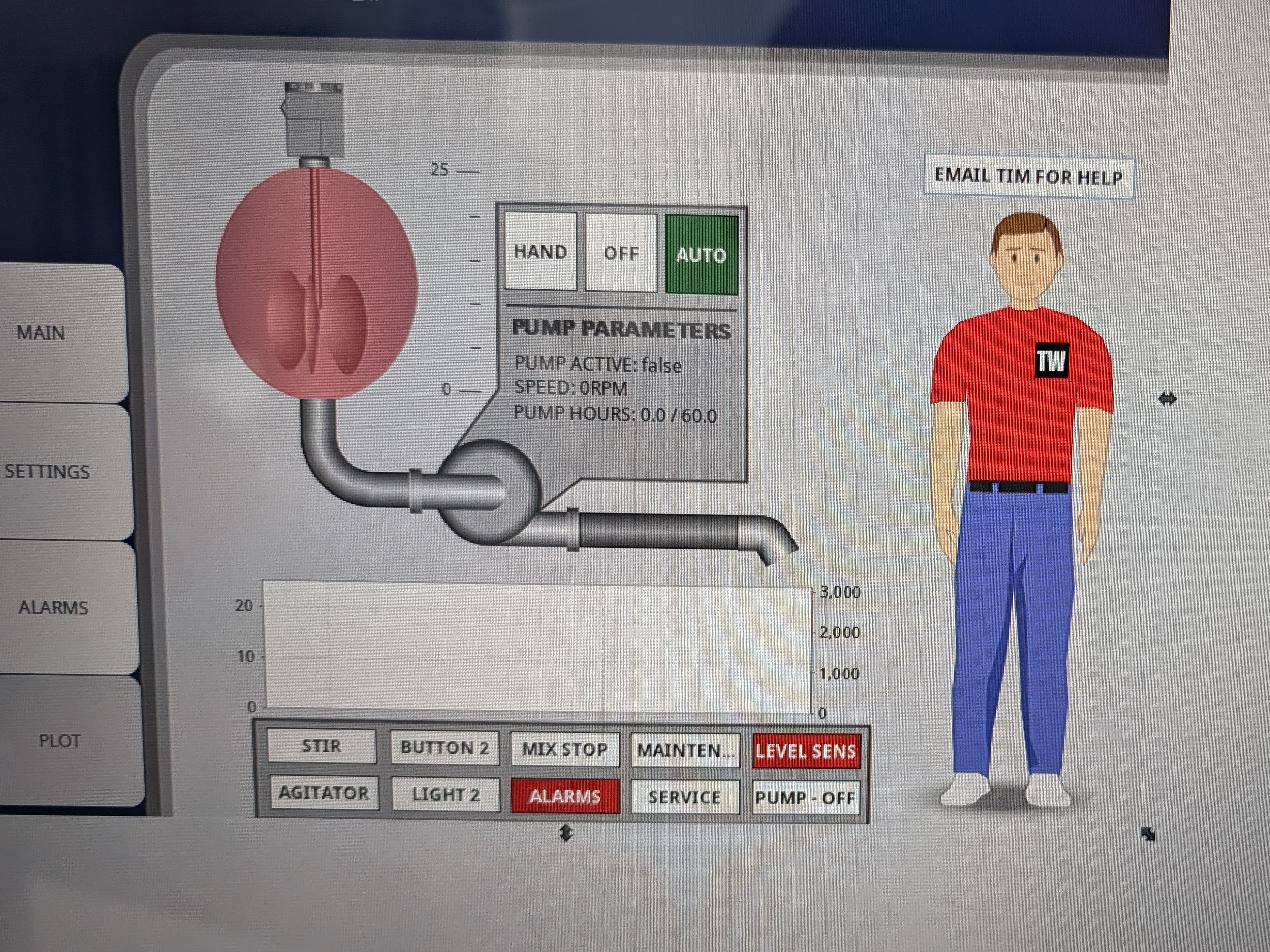

SCADA and HMI Development: We'll start by building the human-machine interface, just as you would for a physical machine. This includes designing screens with controls, graphics, and alarms that directly address the client's requirements.

Data Management: You'll build the framework for data logging, trending, and reporting. The project scope details specific data points to track, such as pump runtime, OEE, and energy usage, giving you a clear objective to work toward.

Security and User Management: You’ll to configure user authentication, roles, and permissions to ensure system security. This is crucial for real-world applications where different users have varying levels of access.

Communication Protocols: You’ll connect to external devices including Allen Bradley and Siemens PLCs using common protocols including Ethernet/IP, Modbus, and OPC-UA.

Web Development & Mobile Integration: Show how to create web-based dashboards and integrate with mobile devices. This aligns with modern SCADA trends and makes the training more relevant.

By focusing on a detailed project scope rather than a physical machine, this workshop allows you to concentrate on the crucial skills of planning, design, and implementation. You will learn to read between the lines of a client's request, identify potential issues, and build a robust, scalable solution. By the end, you'll have the confidence to approach a new integration project, knowing you can turn a document into a functioning system.

Skills that you will learn.

HMI/SCADA Development:

Downloading and installing Inductive Automation’s Ignition

Creating a basic operator screen such as start, stop, and tank level indicators.

Designing a settings screen to adjust parameters.

Building an alarms screens.

Best practices for screen navigation

Developing graphical indicators.

Adding real-time input and output indicators for troubleshooting.

Data Management & Reporting:

Logging system usage and pump runtime for maintenance.

Implementing logic for trend data on variables like tank level and pump speed.

Creating daily system summary reports.

Adding OEE tracking and energy monitoring features.

Building a recipe system to load predefined control parameters.

Alarming & Safety:

Creating alarms and warnings with logic to differentiate them.

Assigning priorities to critical alarms.

Developing multiple alarm listings for active, past, and combined alarms.

Setting up email notifications for specific critical alarms.

Implementing safety-related alarms for E-stops and drive faults.