Hands-On Industrial Automation Training.

Gain practical skills using real-world PLC trainers and industrial hardware in a classroom environment.

Advanced Logic

High-Level IntegrationPLC-203: Studio 5000 Advanced

The ultimate integration course. Bridge the gap between PLC logic and plant-wide systems.

- System Visualization: Connect logic to SCADA and IIoT data structures.

- Analog & Math: Apply scaling and PID loops to complex projects.

- Troubleshooting Review: Diagnostic skills for high-speed industrial networks.

PLC-201: Advanced Troubleshooting

Go beyond basic repair. Learn to resolve the complex system problems that cost your company time and money.

- Industrial Networking: Configure EtherNet/IP, IP addressing, and messaging.

- Peer-to-Peer: Program multiple PLCs to share data via Produced/Consumed tags.

- Proactive Diagnostics: Write code and HMI screens that pinpoint faults for you.

PLC-102: Skills Refresher

Self-guided one-day lab. Review wiring, communications, and troubleshooting at your own pace with instructor support.

View Details →Specialized

SafetyMachine Safeguarding Seminar

Comprehensive training on safety standards, risk assessment, and implementing reliable safeguarding control systems.

View Details → SensingSensor Training

Selection, wiring, and calibration of inductive, ultrasonic, and laser sensors for industrial applications.

View Details → Fluid PowerPneumatics Training

Improve your fluid power and actuator control with live SMC product showcases and PLC integration.

View Details → SoftwareSCADA-101

Data visualization, database logging, and plant-wide IIoT connectivity for supervisory control.

View Details →Why Train With TW Controls?

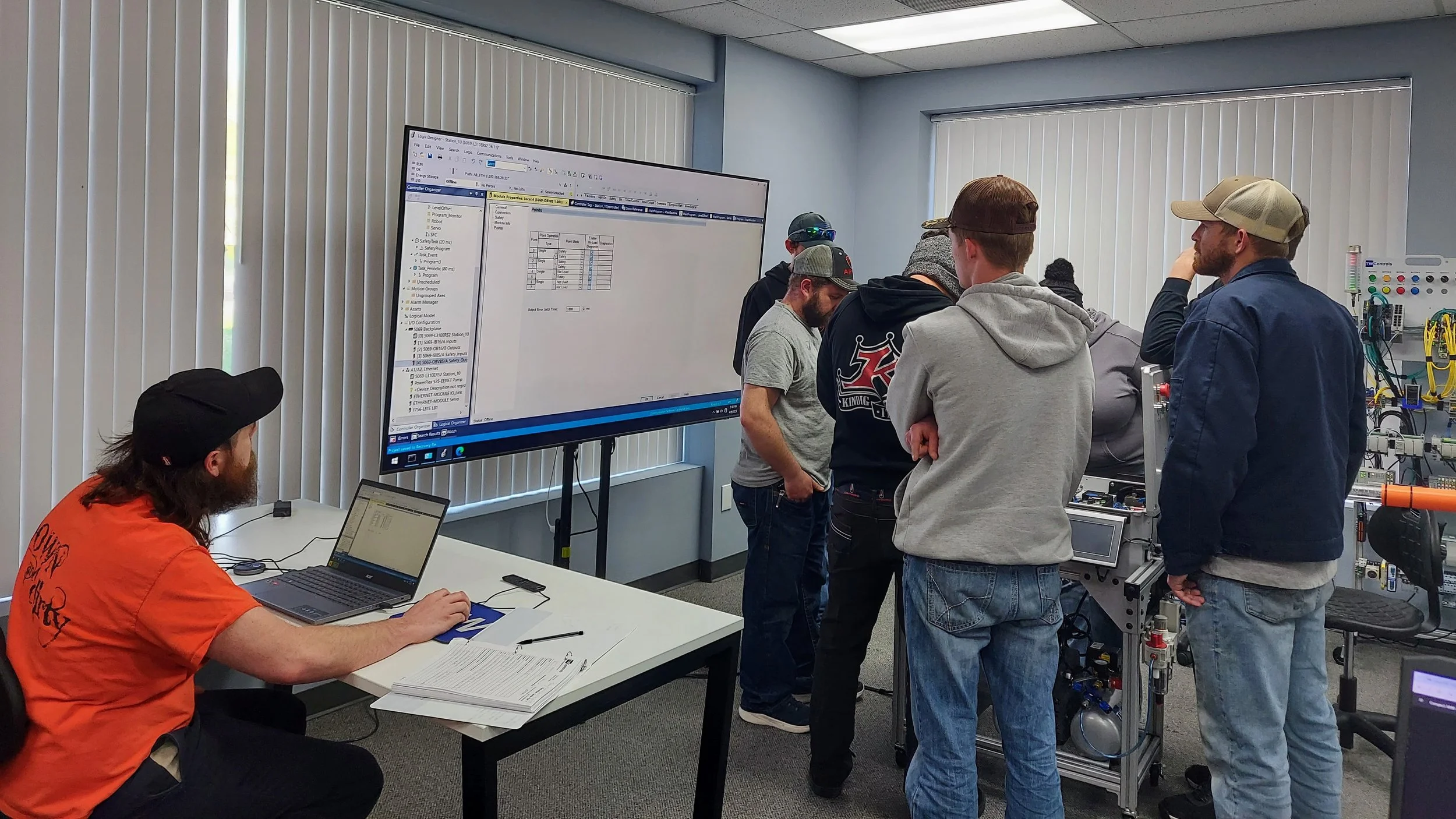

Dedicated Hardware for Every Student We believe you learn with your hands, not by watching a projector. You will not be sharing a trainer or using simulation software. Every student is assigned a dedicated industrial PLC trainer equipped with real components—the same hardware you find on the factory floor.

Instruction from Real-World Integrators Our instructors aren't just reading from a manual; they are active integrators who solve automation problems in the field every day. This means you learn current industry standards and practical techniques that textbooks often overlook. We keep class sizes small to ensure you get direct, one-on-one assistance when you need it.

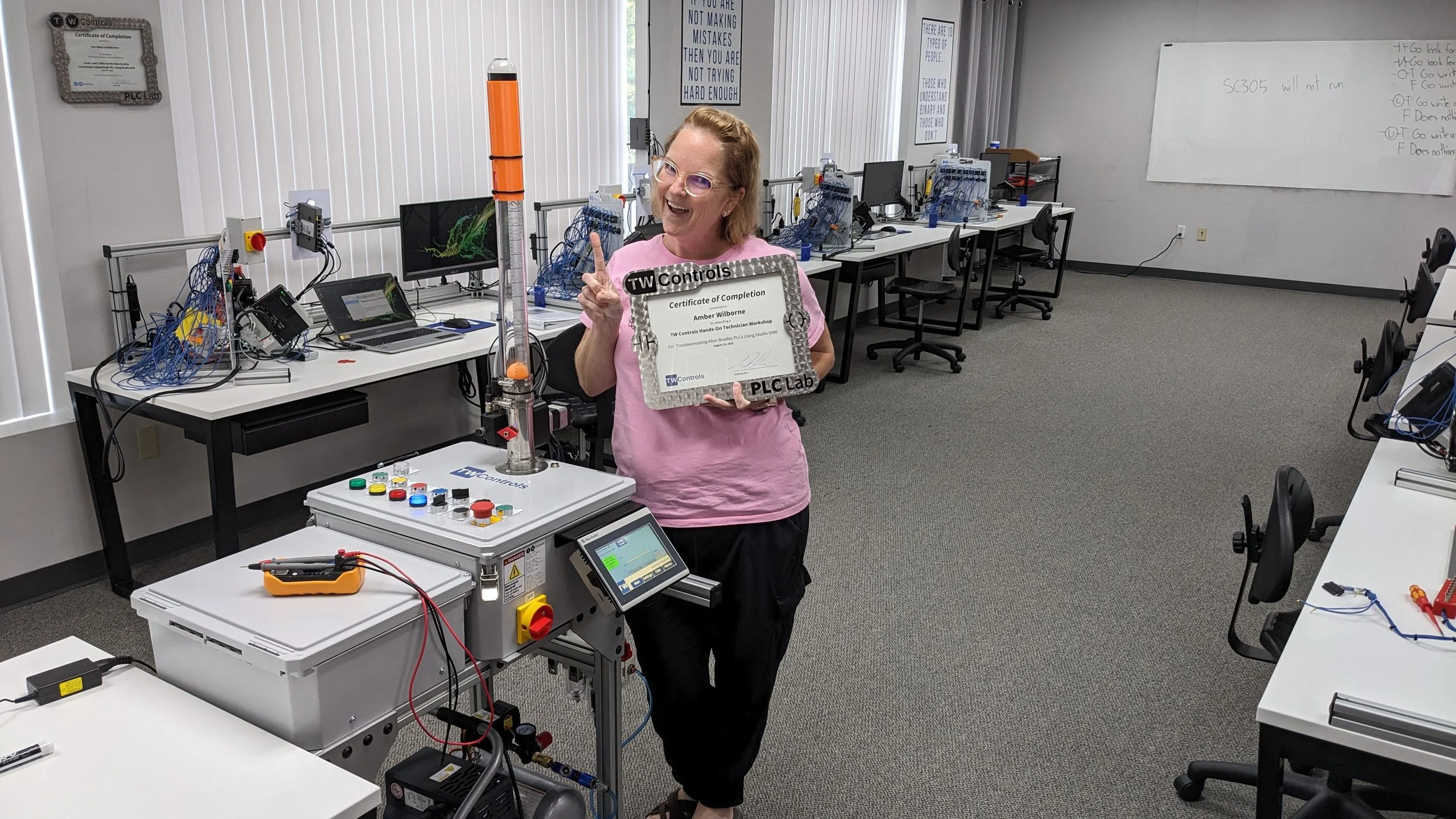

Focus on Immediate ROI Our goal is to make you a better technician the moment you return to work. Every lesson is structured around reducing machine downtime and improving troubleshooting efficiency. You will leave with the confidence to open any control panel, identify the components, and systematically diagnose faults.

Location and Logistics

Roanoke, Virginia Training Center All in-person classes are held at our facility in Roanoke, VA.

Travel: We are conveniently located near the Roanoke-Blacksburg Regional Airport (ROA).

Lodging: Several hotels are within a 5-10 minute drive of the lab. We can provide a list of recommended accommodations upon request.