PLC Lab: Advanced Troubleshooting and Industrial Networking

Go beyond basic troubleshooting and solve the problems that cost your company time and money. This 100% hands-on course moves you from reacting to issues to resolving them permanently.

CLASS: PLC-201 - Advanced Troubleshooting and Industrial Networking

LENGTH OF TIME: 2 Days

LOCATION: Roanoke, VA

COST: $2,000 per person

You must attend the PLC-101 - PLC Training for Technicians class before you can sign up for Integration Week.

Just like our PLC Training for Technicians class, this one isn’t full of lectures, this is 100% Hands On / Minds On training. We move beyond basic troubleshooting to tackle the real-world problems that cost you time and money.

What You'll Learn:

Networking: We'll dive deep into making devices talk to each other. You'll learn to set up Ethernet/IP to connect PLCs, HMIs, and VFDs so they work together as a single, coherent system.

Protocols: These are the rules that devices use to communicate. Ethernet/IP is a popular industrial protocol that uses standard Ethernet hardware, making it versatile and widely supported.

Physical Connections: This involves the cables and hardware that physically link the devices. It's important to use robust, industrial-grade components that can withstand harsh factory environments.

IP Addressing: Each device needs a unique address on the network to be identified. Similar to a home network, devices like PLCs and HMIs are assigned IP addresses to enable communication.

Network Topology: This refers to the layout of the network. Common topologies include star, bus, and ring. The choice of topology affects network reliability and performance.

System Integration: This is the process of bringing all the components together. You'll configure the software on each device to ensure they can send and receive data correctly, allowing them to function as a single, synchronized system.

Peer-to-Peer Communication: We'll program multiple PLCs to share data and coordinate actions. This is all about making your automation smarter and more efficient.

Produced and Consumed Tags: Produced and consumed tags are used in Allen-Bradley PLCs to share data between controllers. A produced tag is data that one controller sends, while a consumed tag is that same data received by another controller. This is a powerful feature for communication between PLCs.

CIP Messaging: CIP (Common Industrial Protocol) messaging is a standard communication protocol used in industrial automation. It enables devices from different vendors to communicate with each other over various networks, like EtherNet/IP.

PLC5 and SLC Messaging: PLC5 and SLC messaging refer to the data exchange methods used by the older Allen-Bradley PLC-5 and SLC 500 controller families. These controllers typically use protocols like DH+ (Data Highway Plus) for communication, which differs from modern EtherNet/IP.

Data Conversions: Manipulating data when it doesn’t come in correctly. This involves programming logic to handle and correct data integrity issues. Examples include scaling analog values, reordering data bytes (byte swapping), or implementing fault-handling routines to address invalid or corrupt data received from another device. This ensures the system operates reliably even with imperfect data.

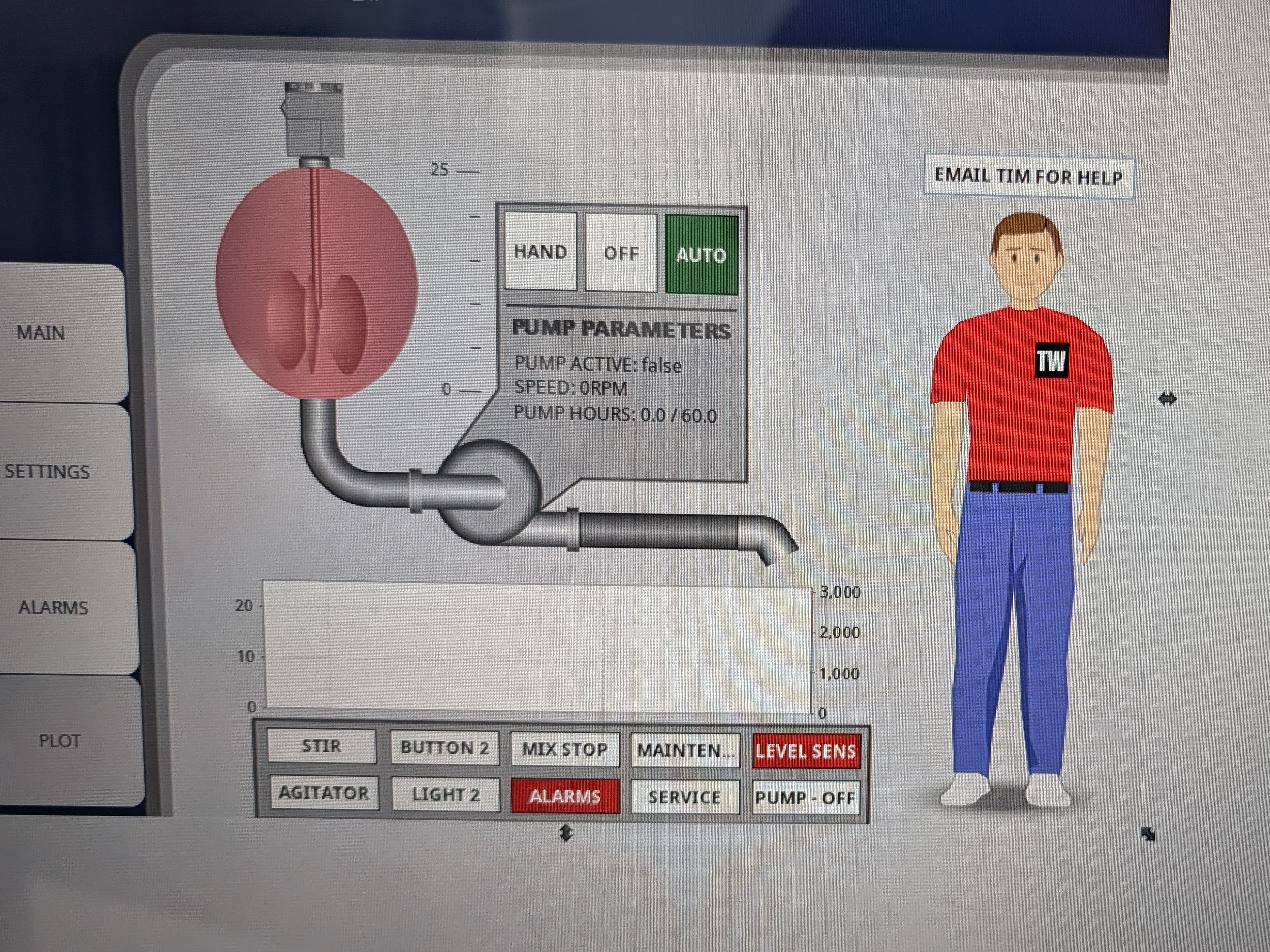

Advanced Diagnostics: We'll show you how to write code that actually helps you find problems, not just run the machine. You'll learn to create custom fault logs and alarms so you can pinpoint issues in minutes, not hours.

Create Custom Fault Logs: Program code to record specific machine states, sensor values, and timestamps whenever an error occurs.

Implement Detailed Alarms: Develop alarms with clear, descriptive messages that identify the exact problem and location.

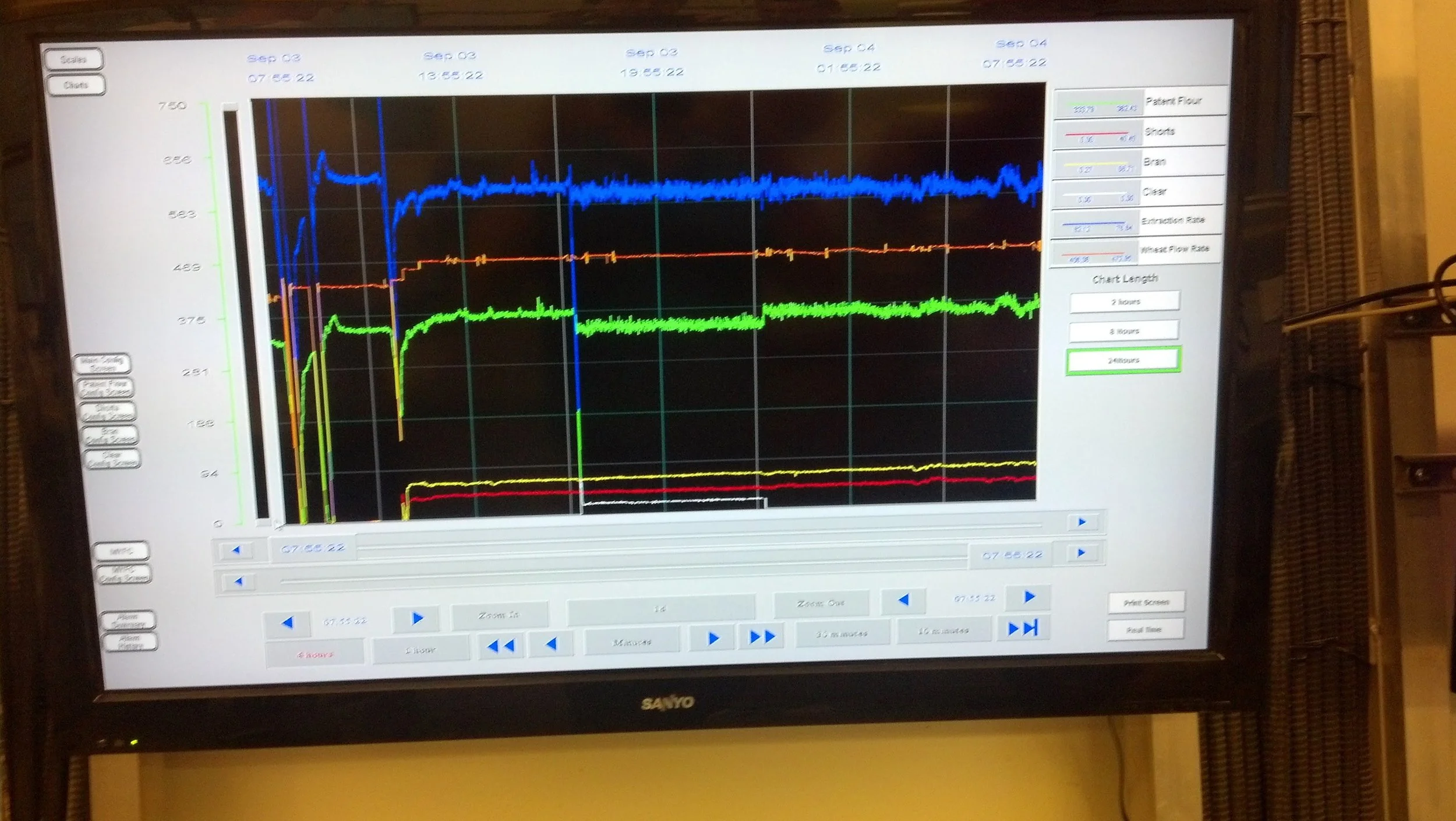

Utilize Historical Data: Learn to use data logging to analyze trends and identify intermittent problems before they cause a shutdown.

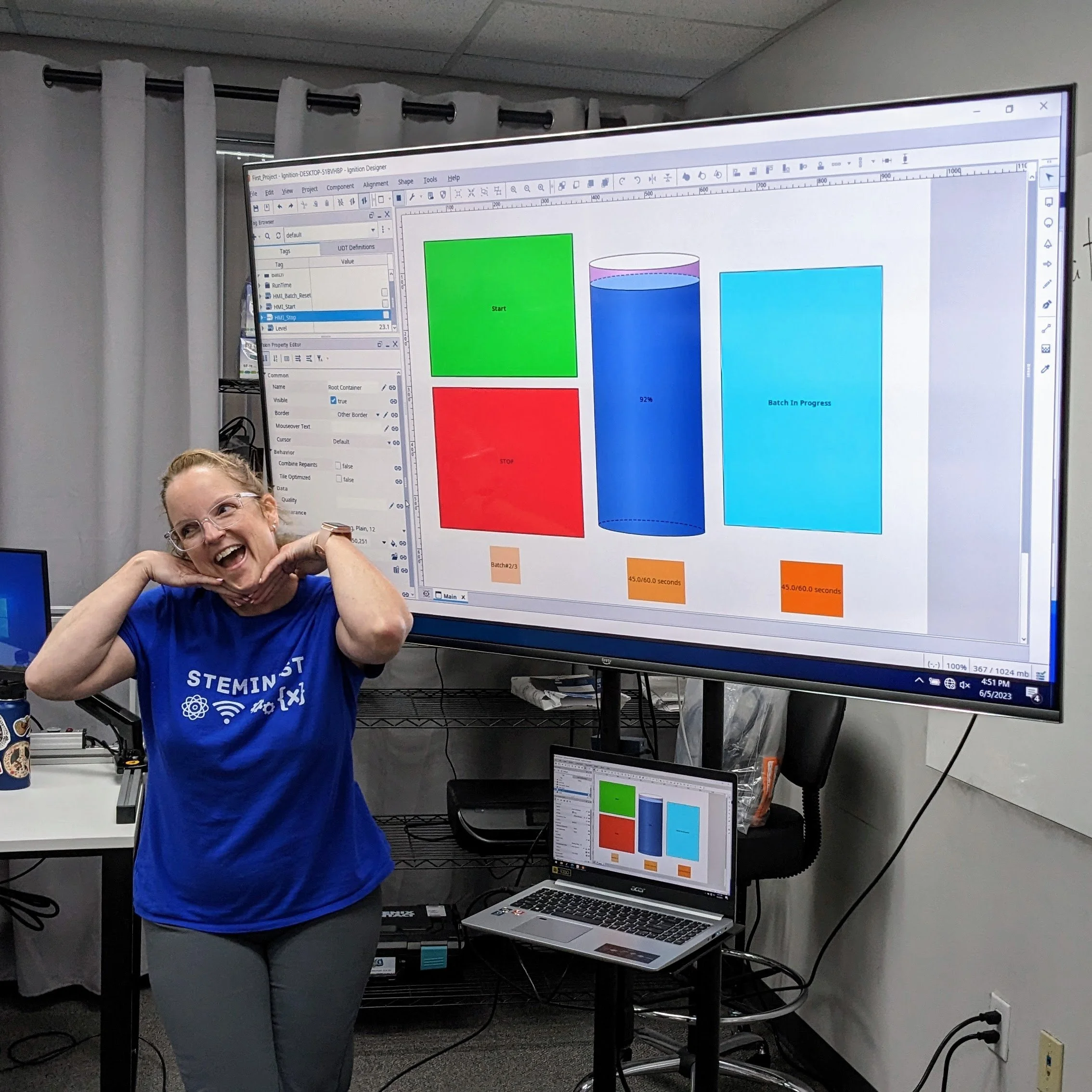

Build HMI Diagnostic Screens: Design operator interface screens that display real-time status, fault history, and troubleshooting guides.

Integrate Third-Party Tools: Discover how to use diagnostic tools and software to monitor network traffic and device health.

The Outcome:

You'll walk away with the confidence to tackle more complex systems. You'll be able to quickly diagnose problems, reducing downtime and saving your company money. This course is for the technician who wants to stop reacting to problems and start solving them, permanently.