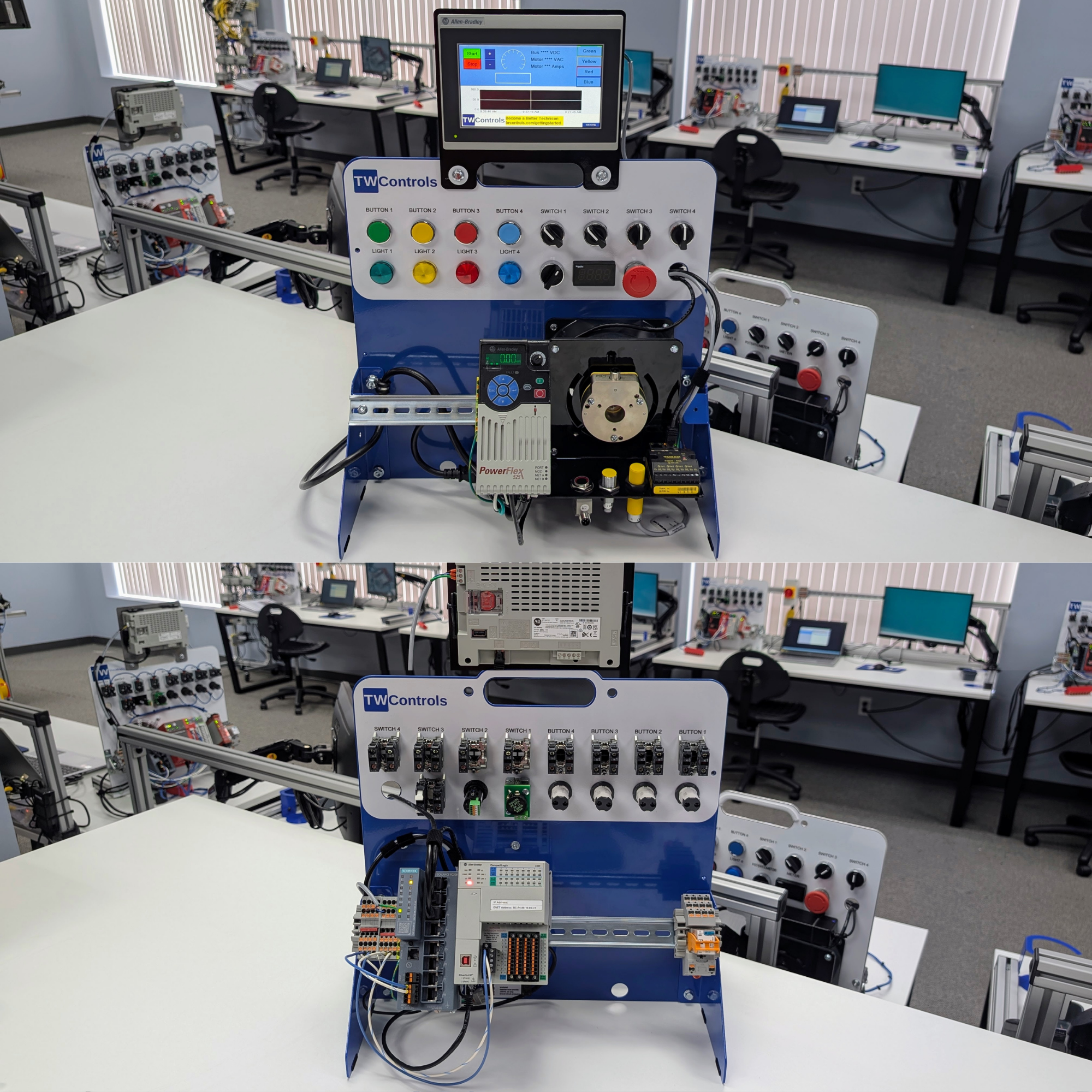

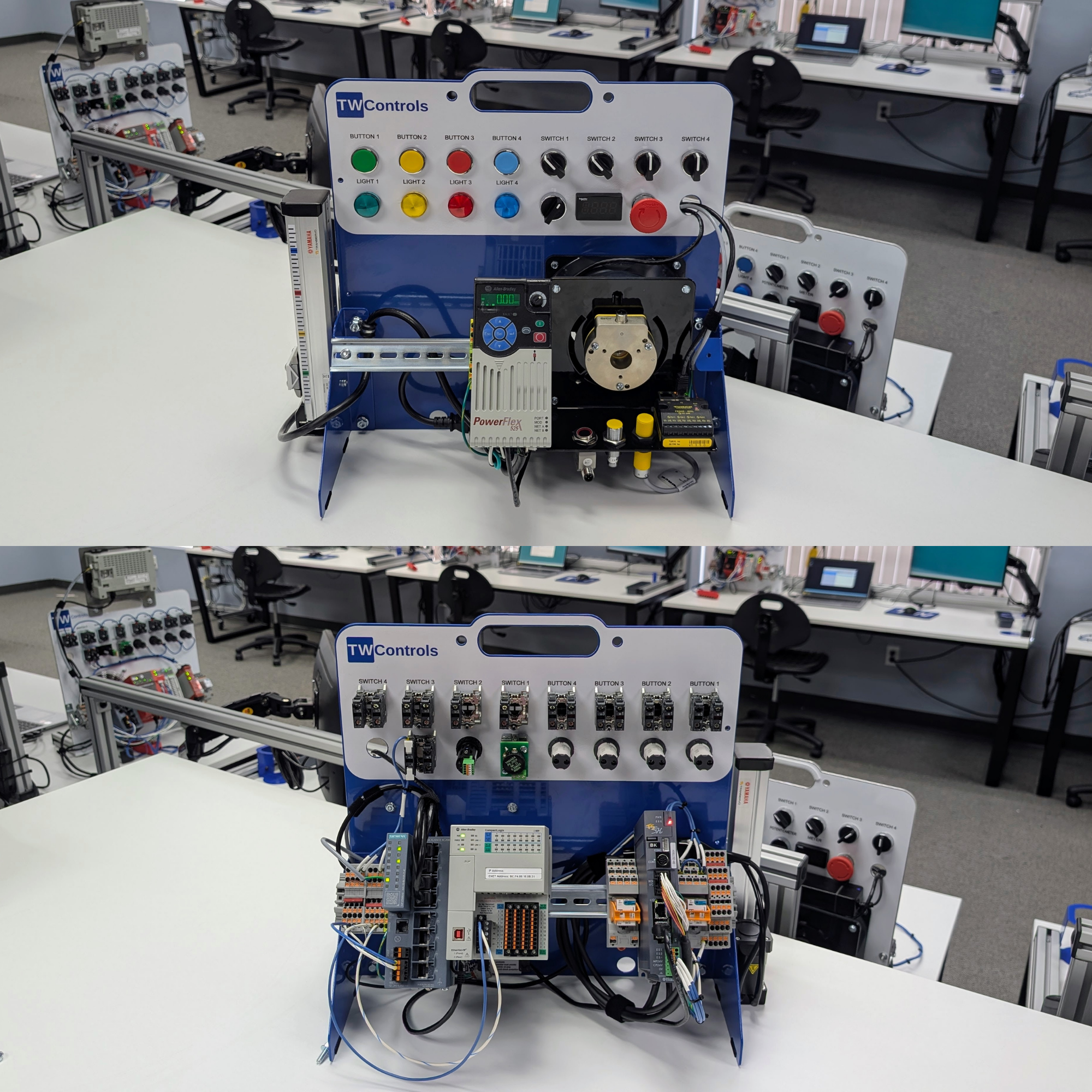

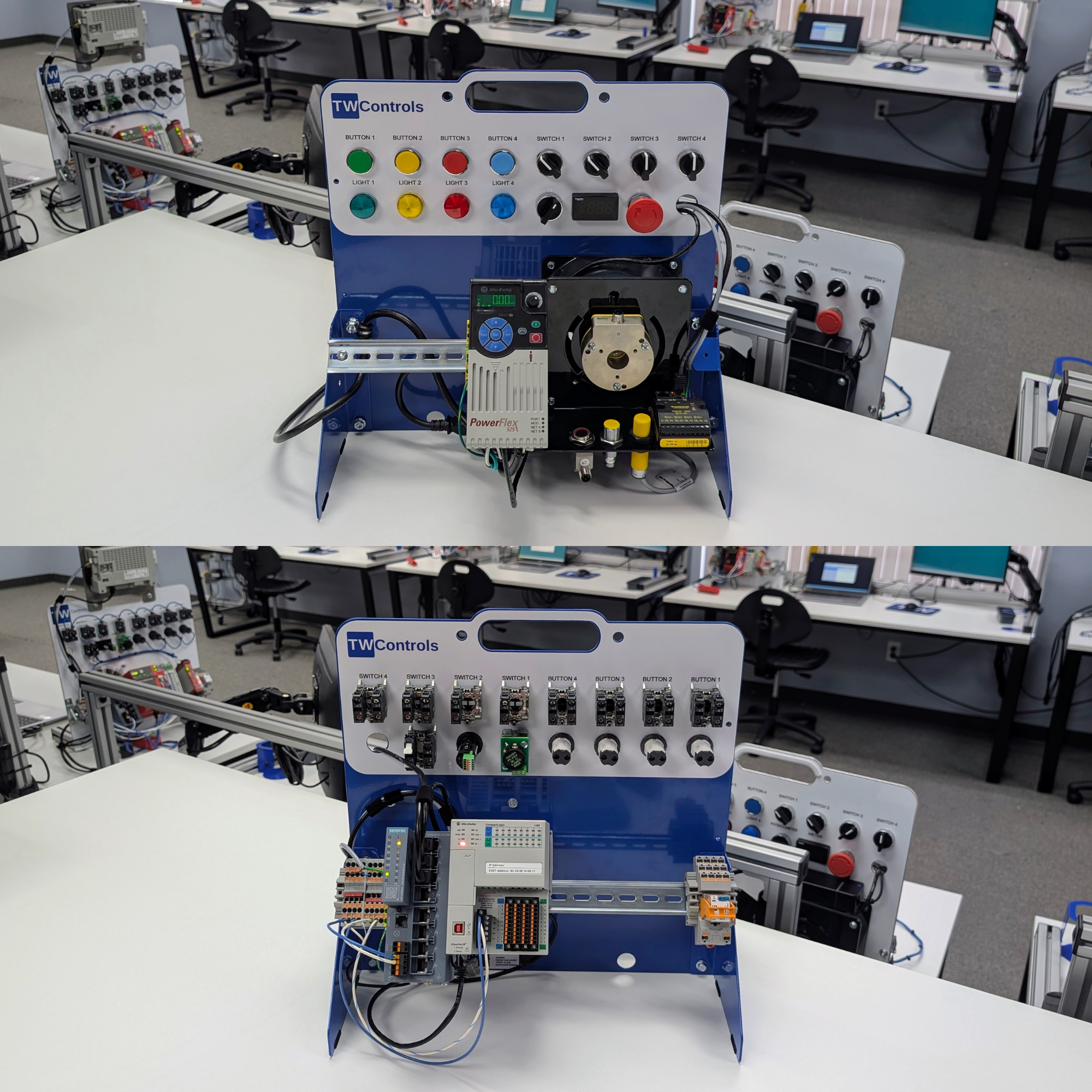

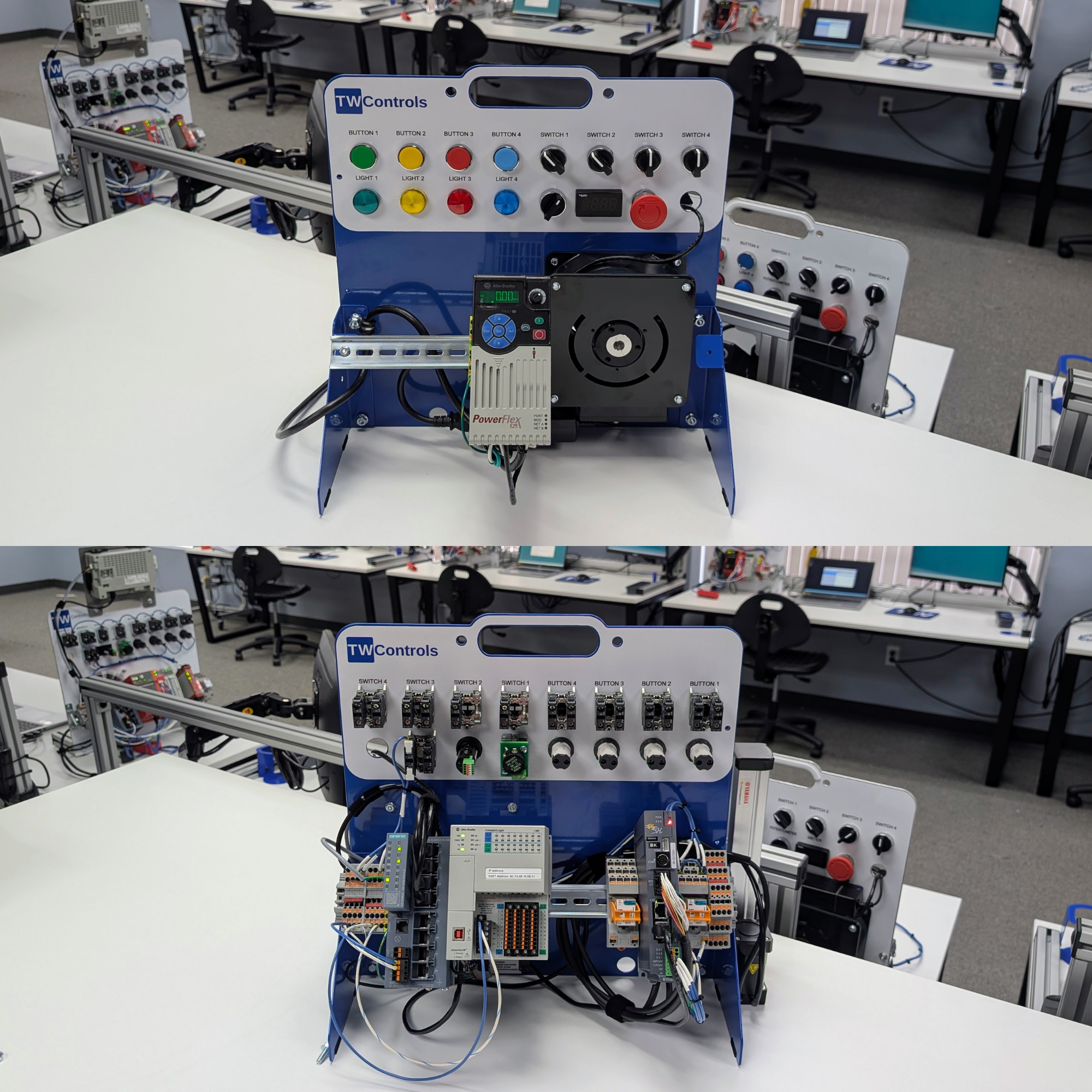

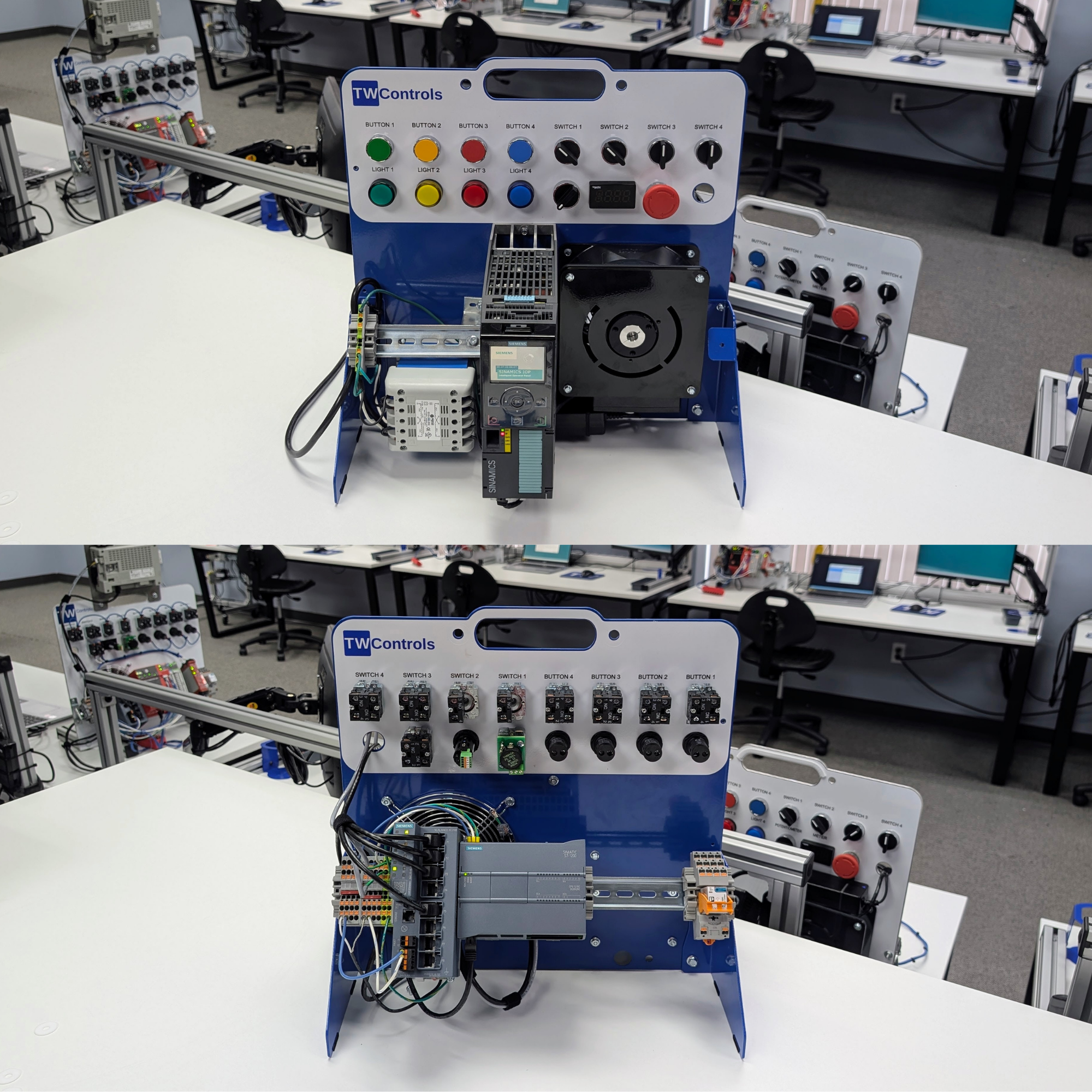

Get the exact PLC trainer you need to succeed in automation and manufacturing.

Lesson provided by Tim Wilborne who has made over 1000 instructional videos and has over 100,000 followers.

Click here to view the Online PLC Courses available for your PLC training.

Not only will you learn about the different programming aspects of manufacturing equipment, you will also learn industrial control wiring, installation debugging, and most importantly troubleshooting systems when they don’t work.

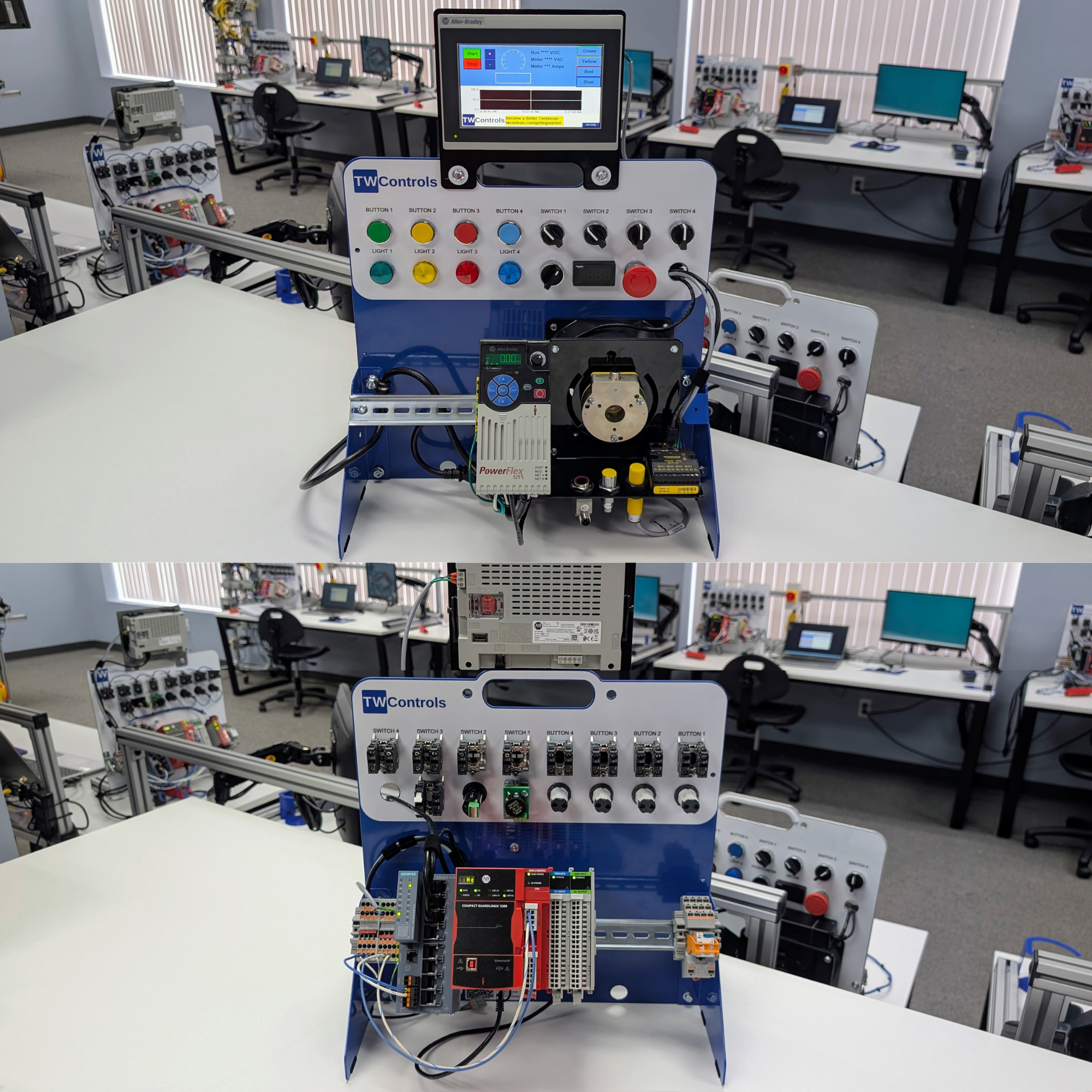

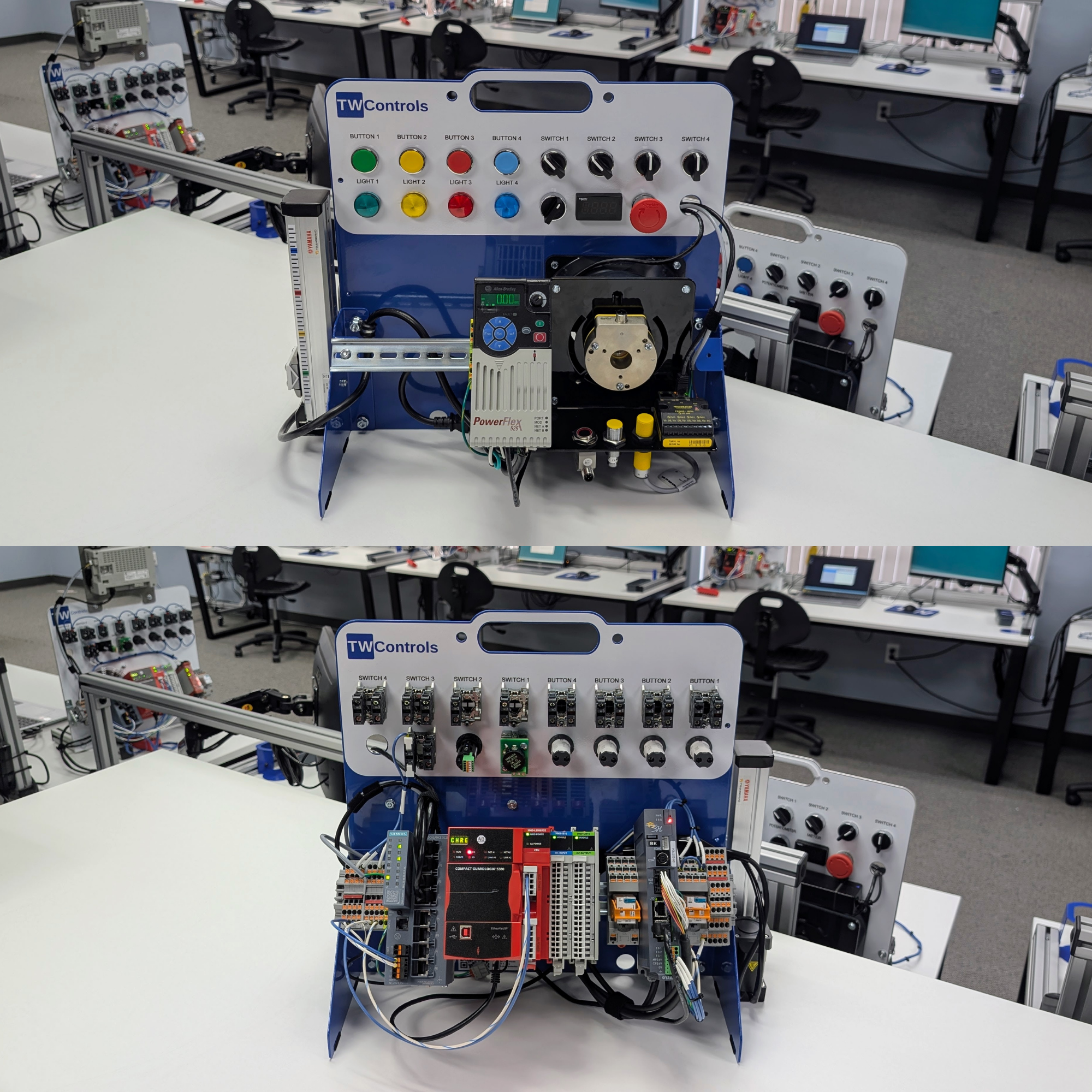

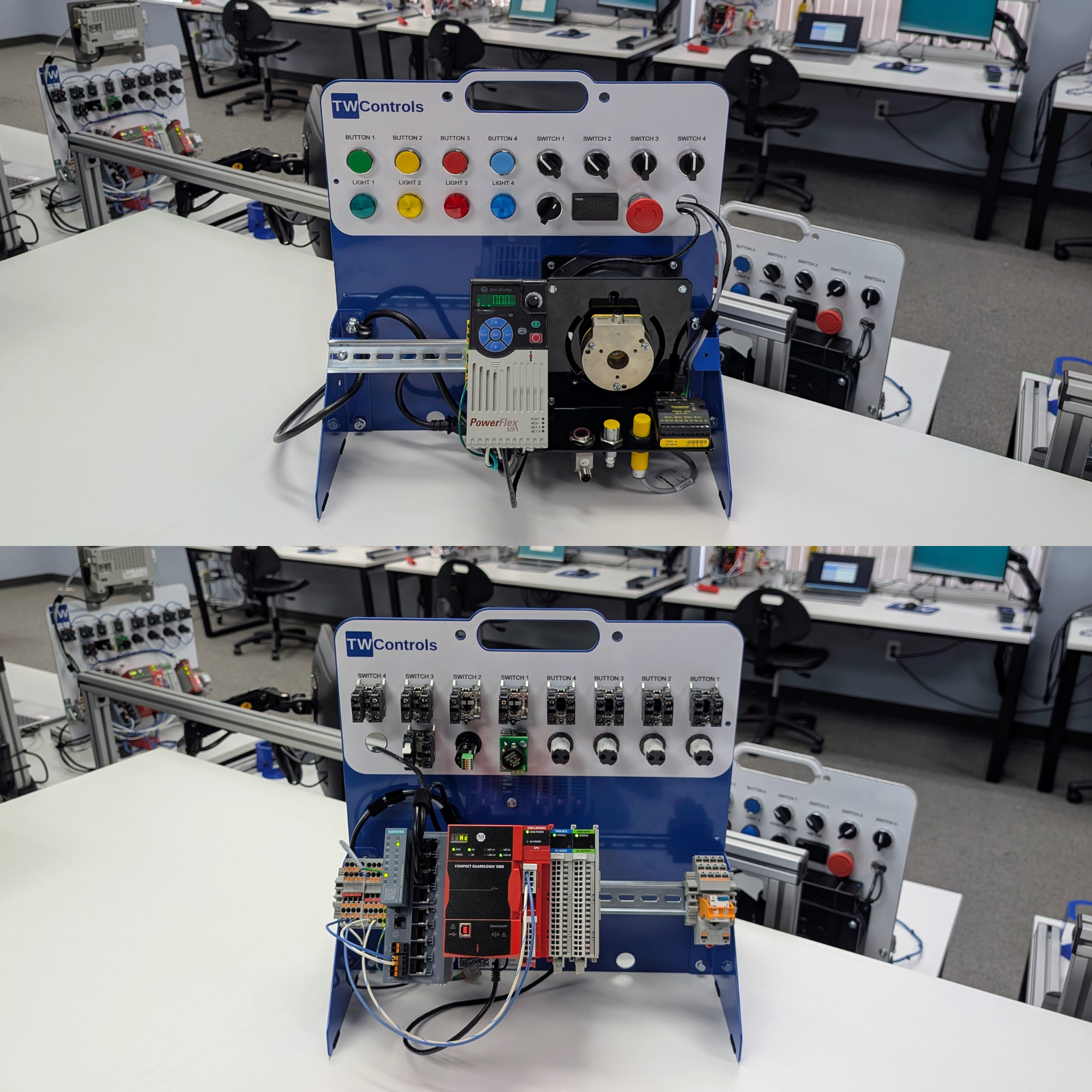

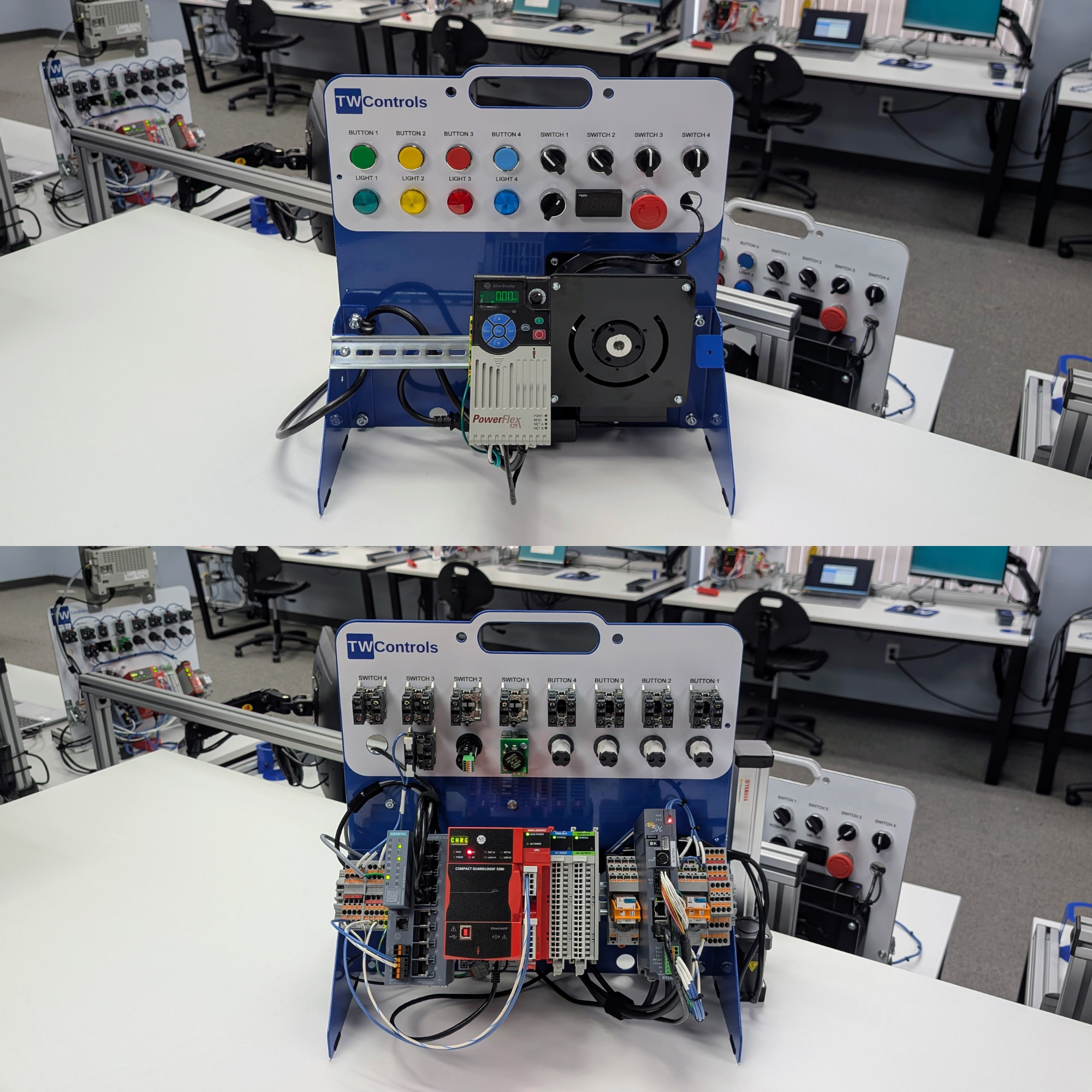

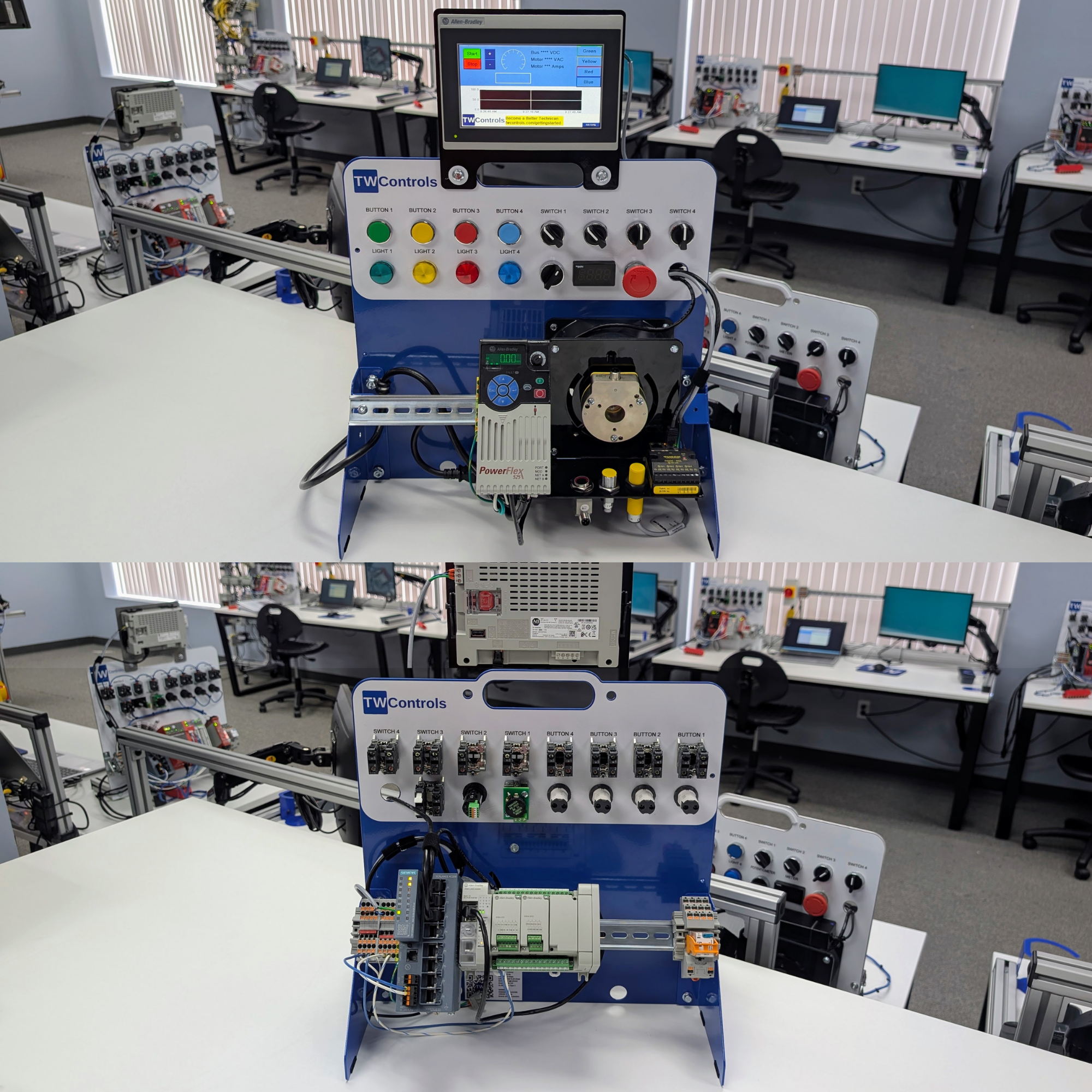

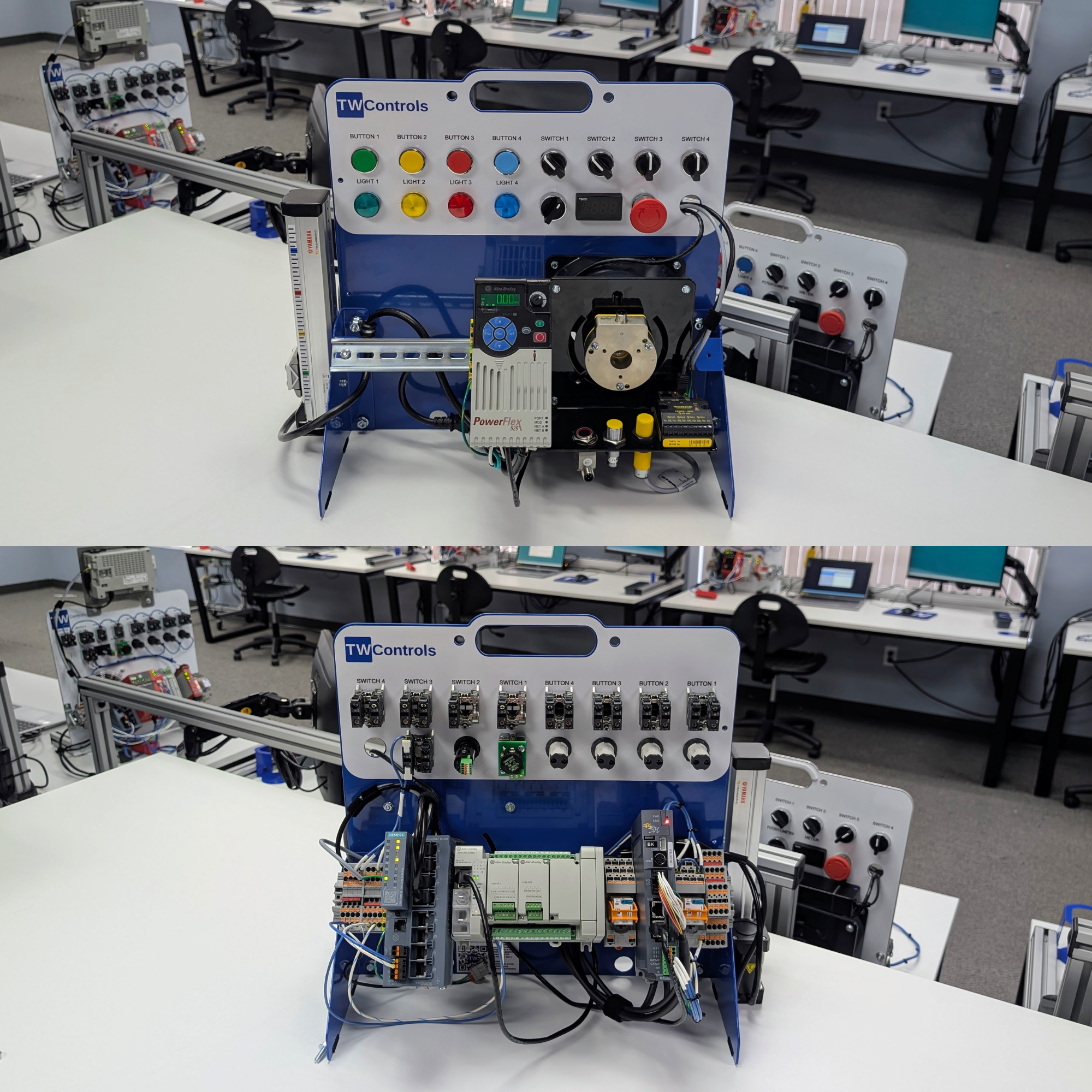

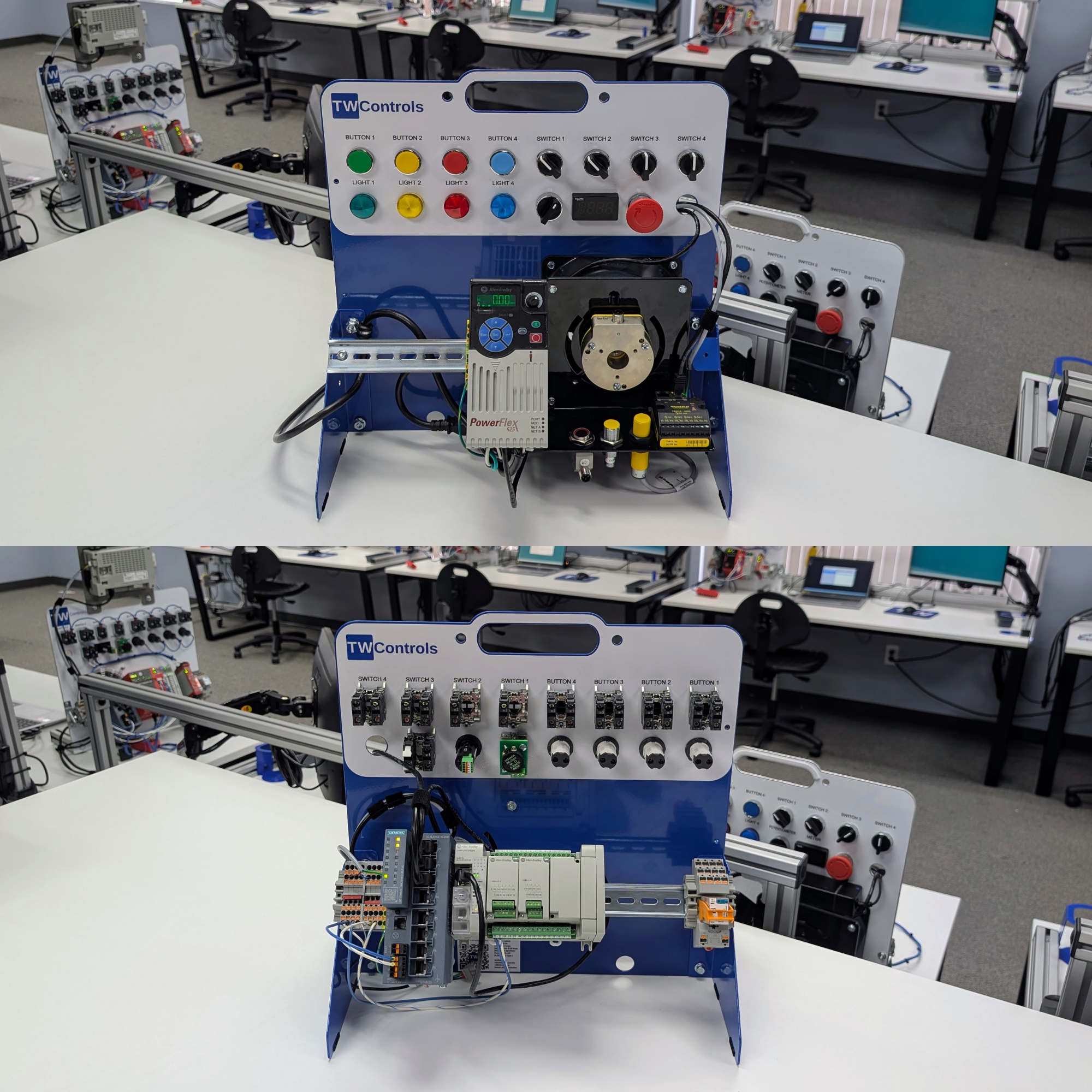

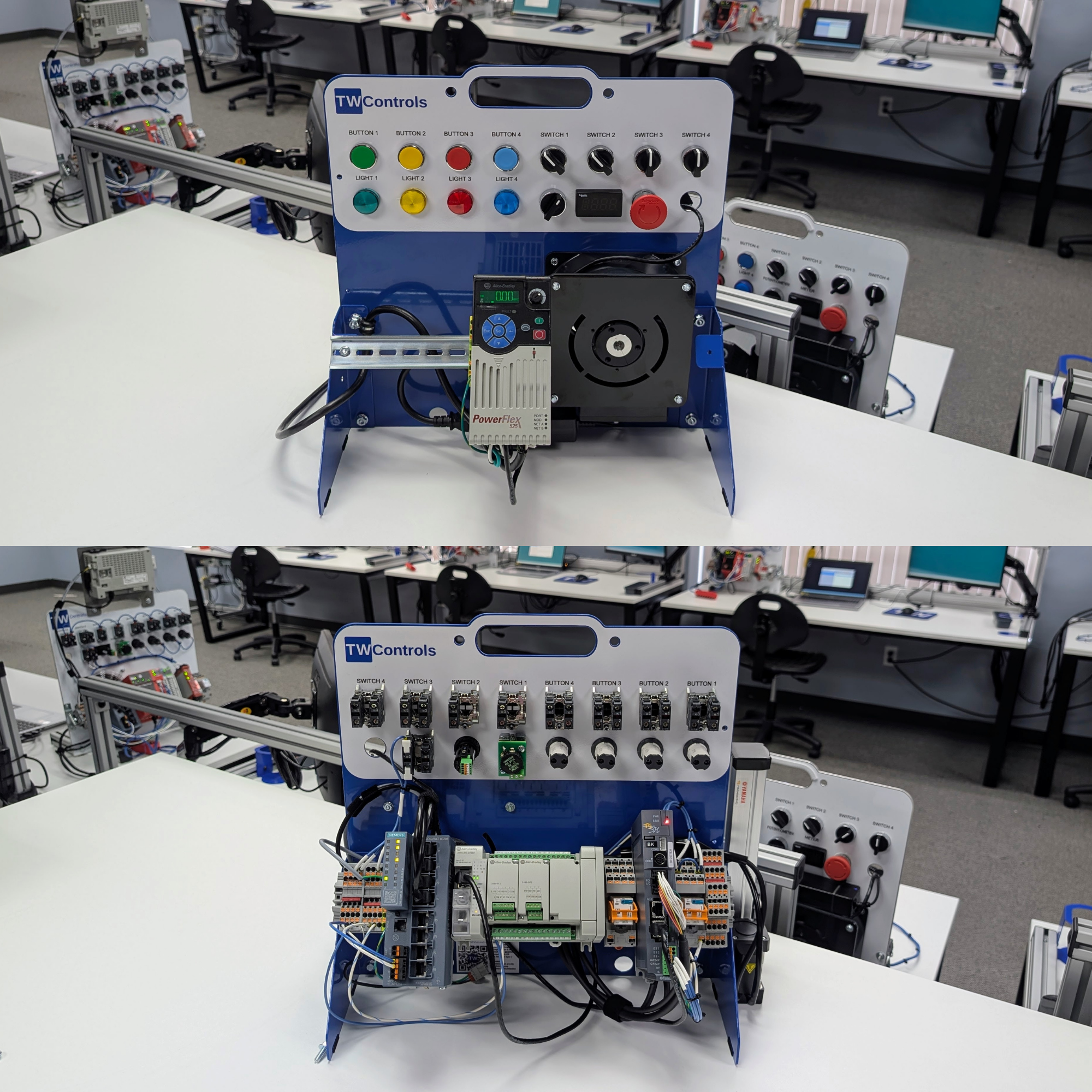

These are the same PLC trainers that we use in our classes. Our hands on approach to learning can be replicated in your technical school, college, or in the comfort of your own home.

Benefits

☑️ Increase skills

☑️ Increase employee retention

☑️ Reduce unplanned downtime risk

☑️ Reduce time to repair

☑️ Improve workforce development

☑️ Prepare for the digital transition

Who is this trainer for:

☑️ Maintenance Technicians

☑️ Instrumentation Technicians

☑️ Automation Technicians

☑️ Engineers and Software Developers

☑️ Students in Engineering and Mechatronics

☑️ Anyone who needs cross-training on PLCs

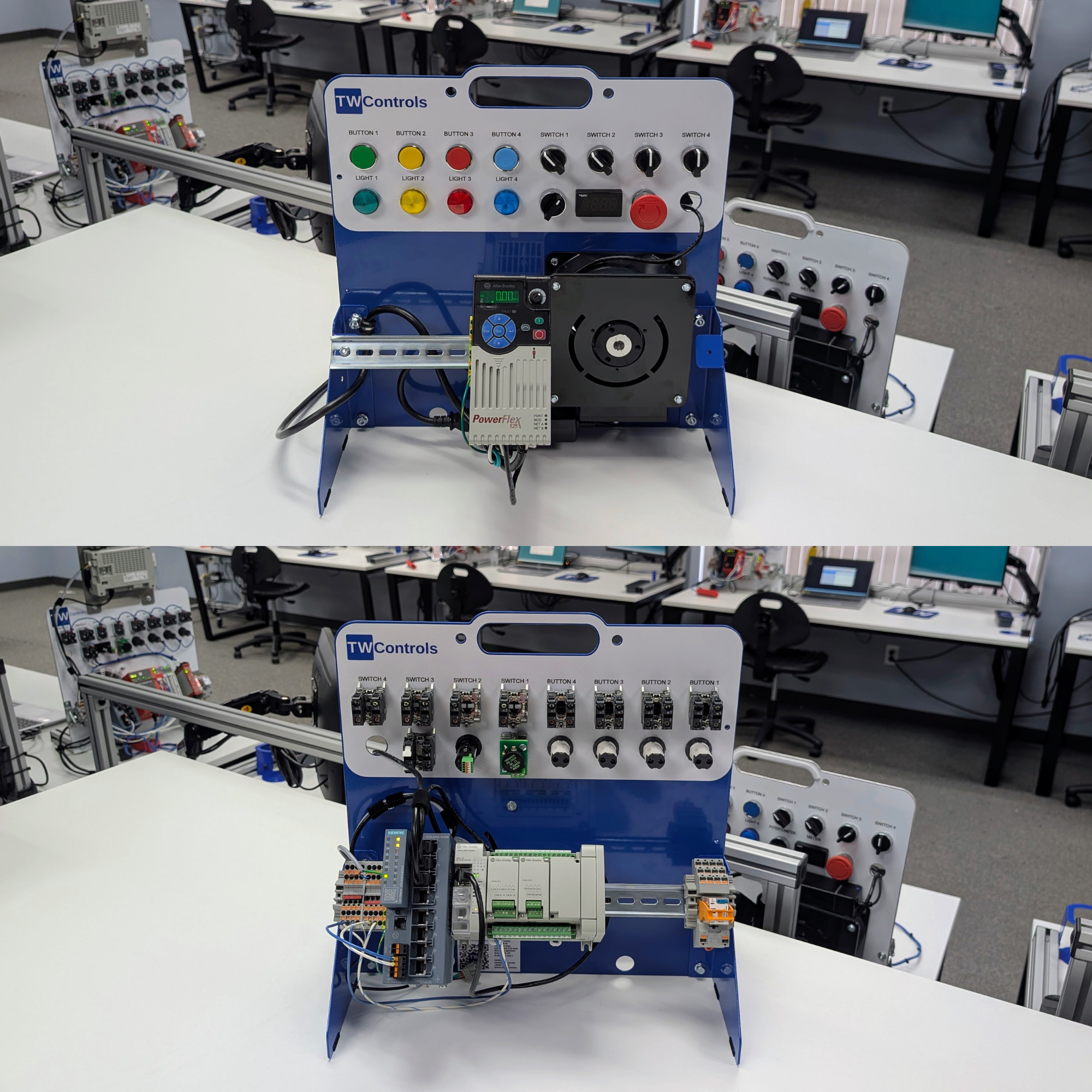

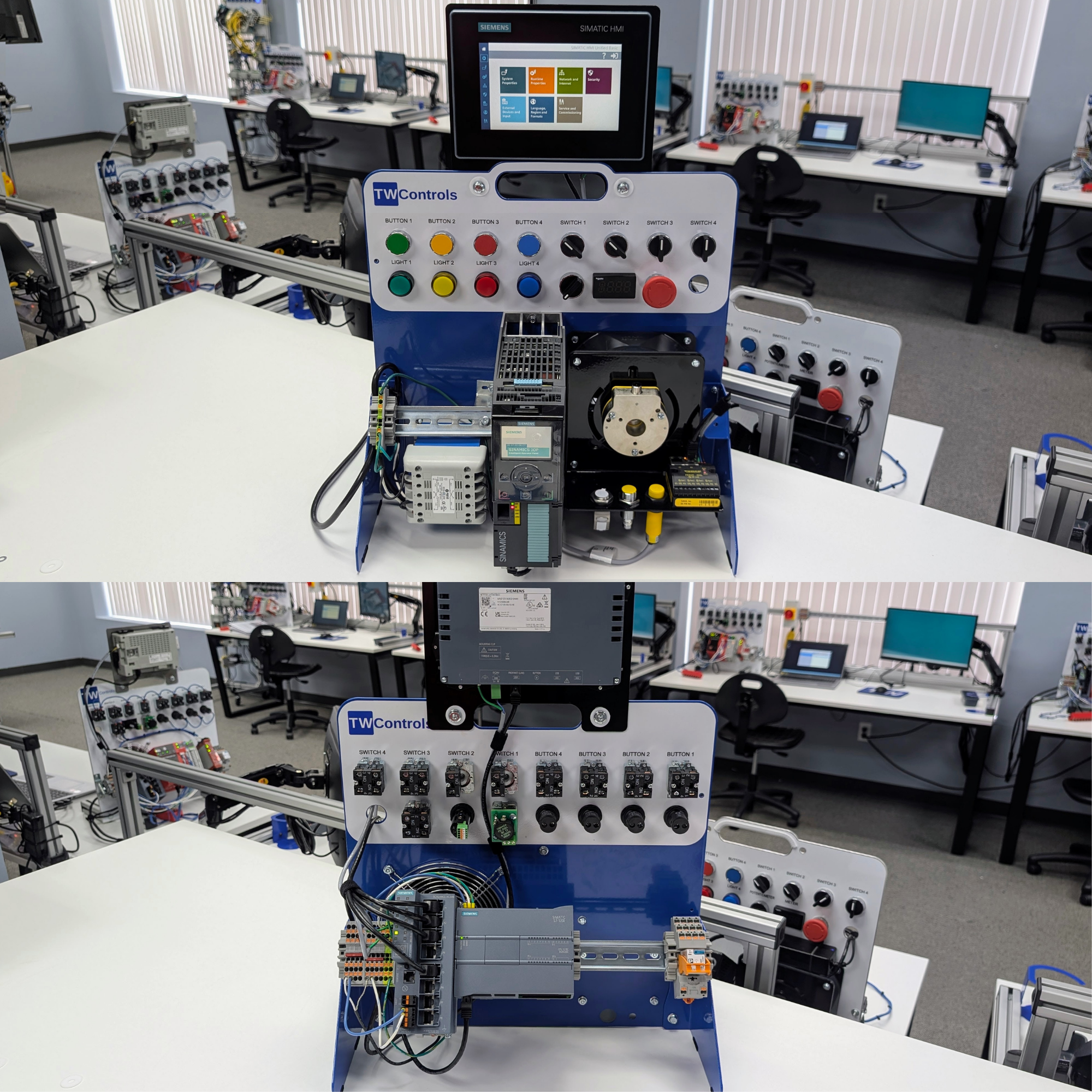

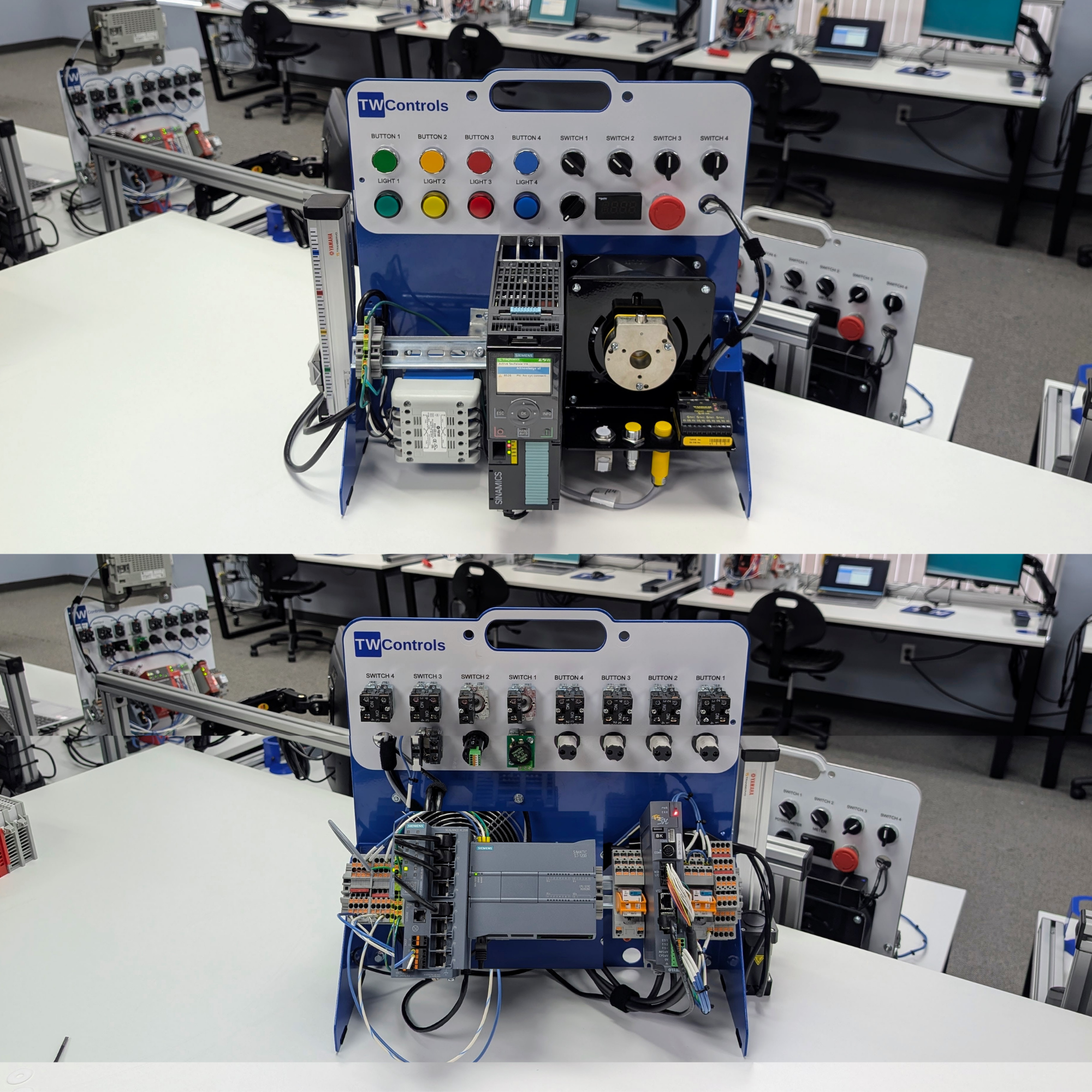

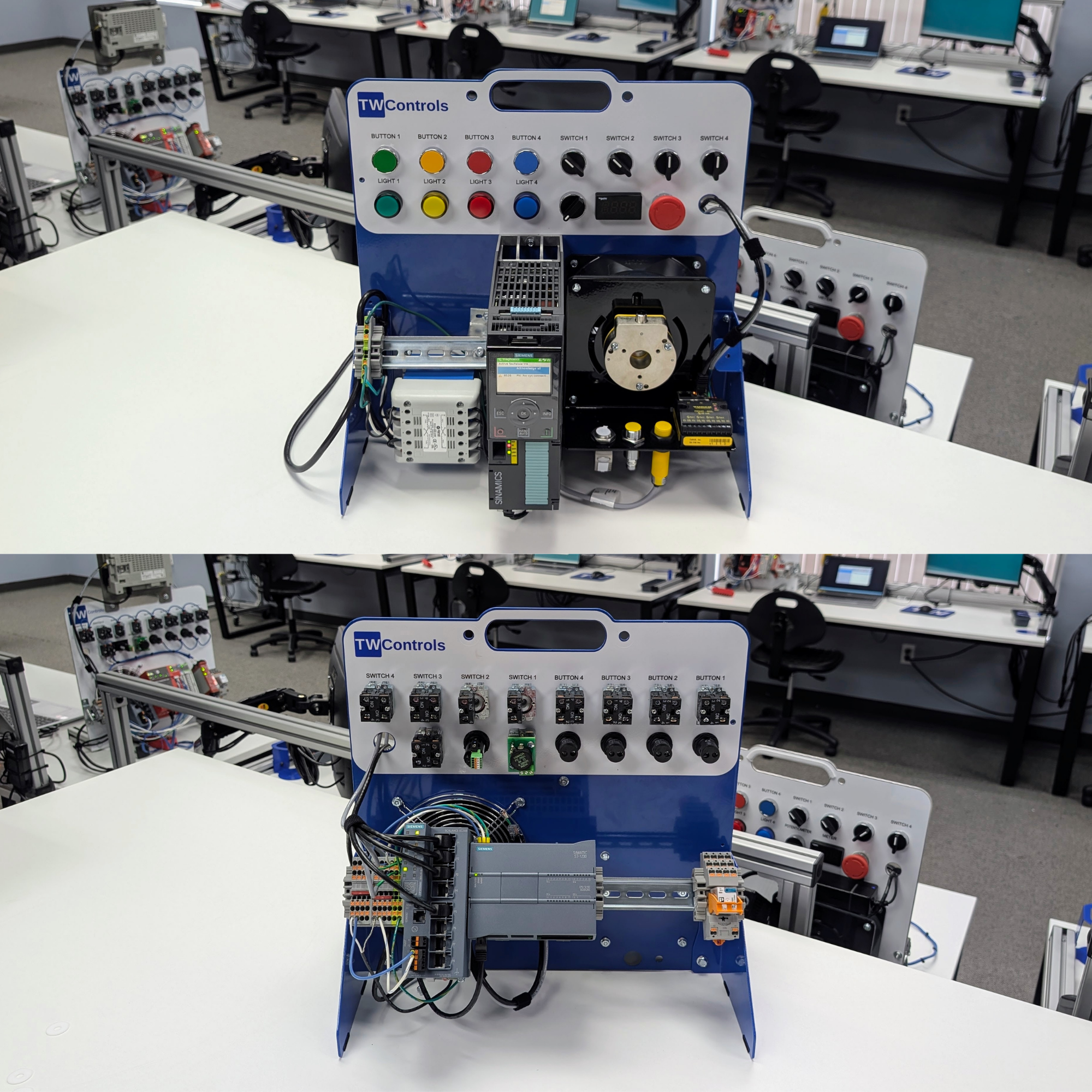

Trainer Features

☑️ 120VAC wall powered

☑️ Portable size for use on table/desk

☑️ Lightweight design

☑️ Optional case for easy transportation

☑️ Free access to online PLC courses

About Us

☑️ Family owned company located in Roanoke, VA

☑️ Established in 2006

☑️ Made in the USA

☑️ Advocates for manufacturing and skilled trades

☑️ Our training center uses these same concepts

What you will learn depending on options selected

PLC and HMI Programming

Downloading, uploading, and going online

Locating I/O tags and devices, tag aliases, forcing I/O, and toggle bits

Basic instructions, timers, and counters

Machine step sequencing methods

Analog scaling and mathematical manipulation

PID Proportional Integral Derivative for process control

Data types and numbering systems

Arrays with 1, 2, and 3 dimensions and manipulating data inside them, indexed/indirect addressing

Add on instructions (AOI) and User Defined Data Types (UDT)

Create and organize a project

Create periodic and event tasks

Common PLC programming languages: Ladder Logic Diagram (LD), Function Block Diagrams (FBD), Structured Text (ST), and Sequential Function Charts (SFC).

Program control JSR, JMP/LBL, FAL

GSV/SSV to get module information, Data/Time, and other advanced diagnostics information.

Password protection

Upgrading and downgrading firmware

Integrating with 3rd party devices

Motion Control for pick and place and industrial robotics applications

Kinetix motion instructions even though this is a non-motion PLC

Can be integrated with cobots

Industrial Control Wiring including AC drives and 3 Phase Motors

Real wire, real terminal screws, and real termination points. You can’t learn to wire UL 508A Industrial Control Panels using 2mm banana plugs

Wiring discrete and analog inputs and outputs, safe for students at 24VDC

Using a multimeter for voltage, amperage, and continuity checks

Reading electrical wiring diagrams and understanding schematic symbols

Sensors, how to wire and the difference between the most common types: photoelectric, inductive proximity, and capacitive

Relays and solid state devices

IO Link., learn about advanced sensors and diagnostics

Basic AC and DC fundamentals

AC drives and 3 phase motors

Powerflex 525 VFD Variable Frequency Drive

AC Induction Motor

Acceleration and deceleration, motor braking, jogging, and protection

Control methods including hardwired start/stop, HOA Hand Off Auto, and Ethernet/IP control

Integrating with PLCs and HMIs

Networking and Cyber Security

Basics of IP address, subnet, and gateway

Configuring your PC to communicate with your PLC over Ethernet

Communicating with remote Ethernet I/O, and distributed I/O

Produced and Consumed tags (between two PLC trainers)

Message Instructions

Realtime data logging and acquisition

Analyze and troubleshoot systems using trend charts

Ethernet/IP in the IO Configuration and Modbus TCP via Add On Instruction (AOI)

Industry 4.0, IIoT, and integrated systems

Remote monitoring and analytics

Alarms and emailing on events

Configuring Ethernet switch, layer 1, layer 2, and layer 3

Industrial Cyber Security

Diagnose and resolve issues with Ethernet switches and devices on a network

Set up one-to-one IP address translation (NAT) for segmenting machine-level network devices from the plant network

DLR Device Level Ring topology for redundancy

Trainers can be interconnected with each other to simulate a manufacturing plant network