Motion control is a fundamental skill for high-speed manufacturing, packaging, and robotics.

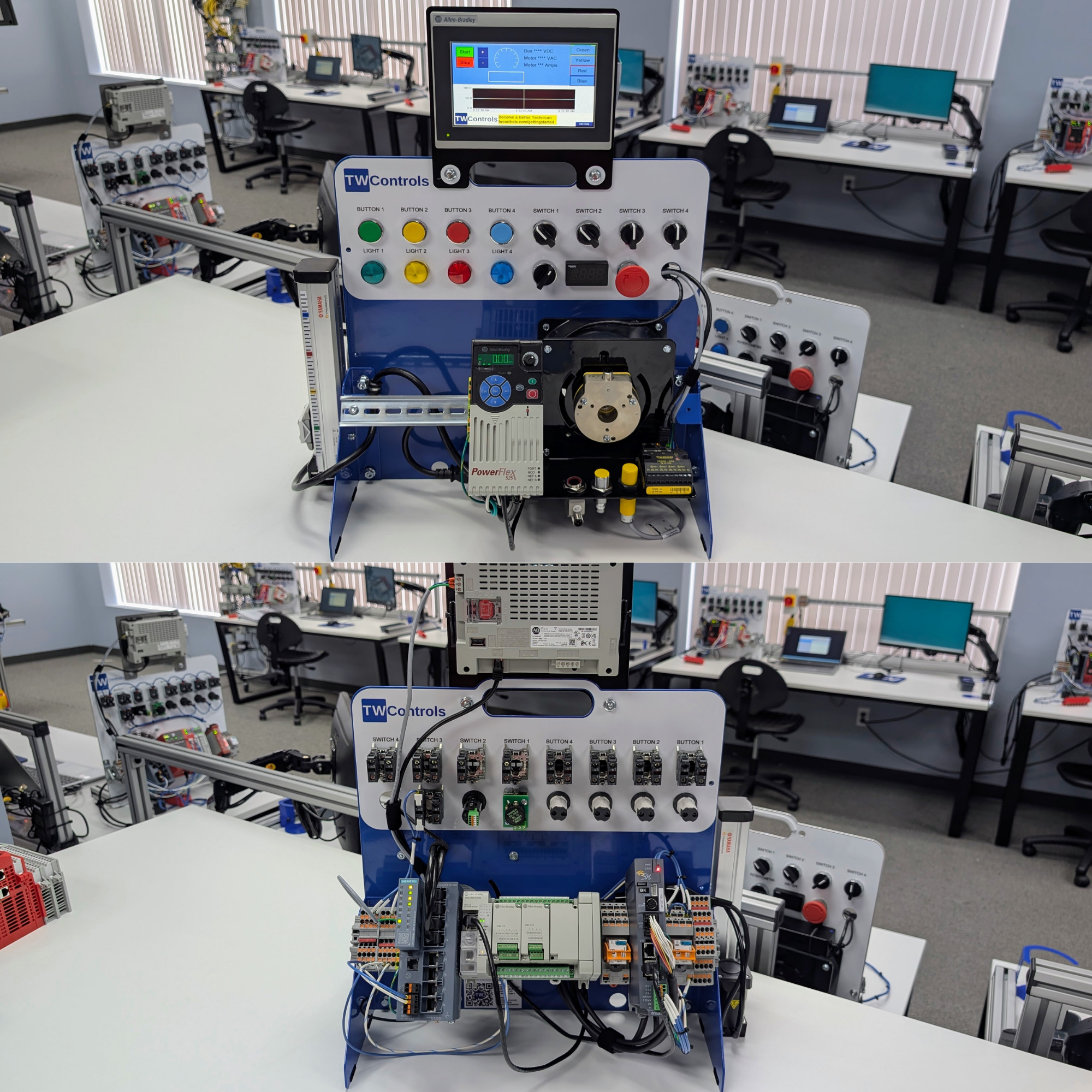

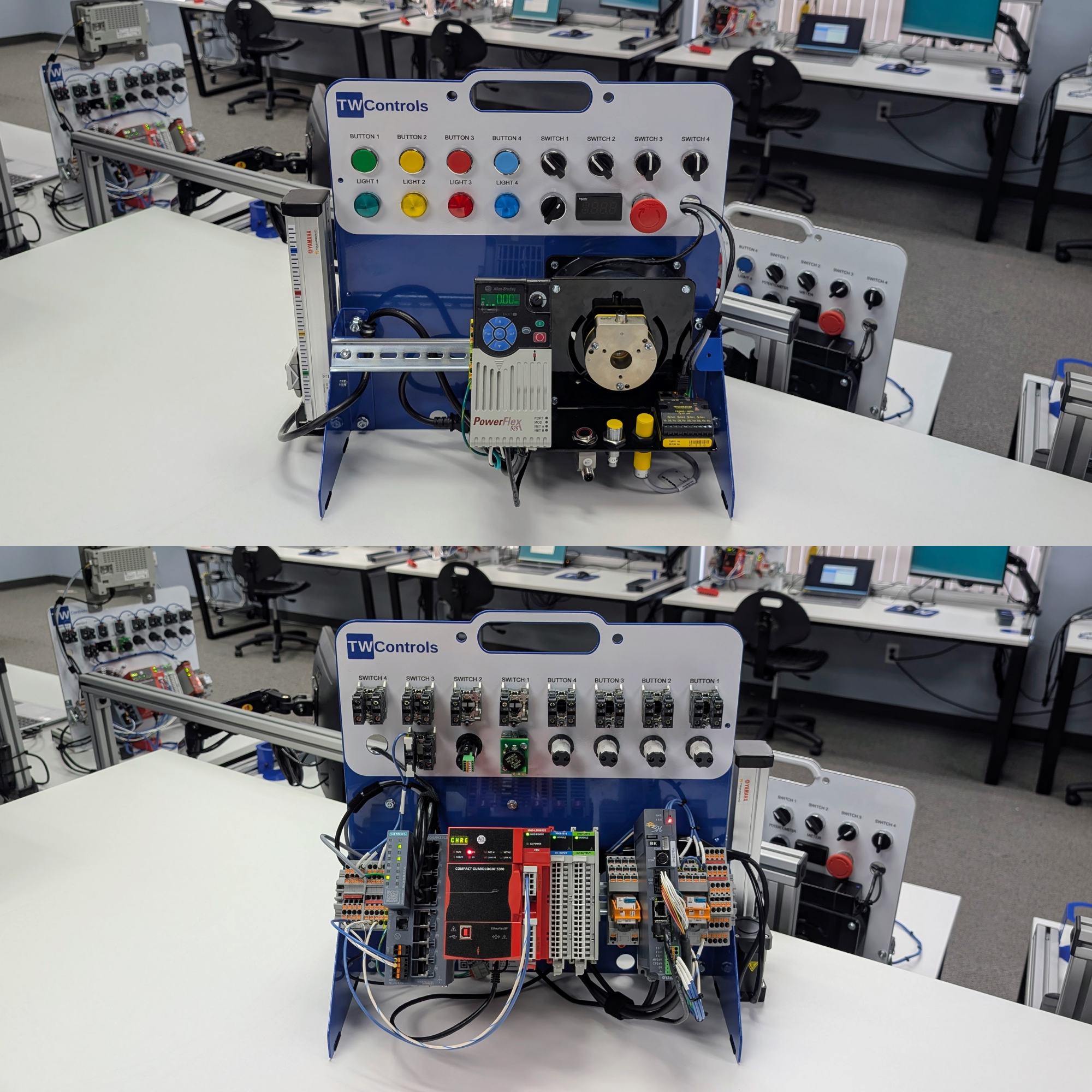

Our trainers are equipped with systems ranging from economical Linear Motion Control (LMC) for foundational learning to high-performance Kinetix Servo Control for advanced, multi-axis applications.

Linear Motion Control (LMC): Foundational and Economical. LMC represents the most accessible and widely applicable form of motion training. It is integrated directly into budget-friendly PLC platforms (like Micro850 and S7-1200) and is ideal for teaching the core principles of precise positioning.

Primary Focus: Mastering closed-loop position control and single-axis movement.

Best for: Technicians supporting simple indexing, pick-and-place, and positioning applications common across a wide range of industries.

Benefit: Provides hands-on experience with the fundamentals of feedback loops and motor control without the complexity or specialized hardware of a full servo network.

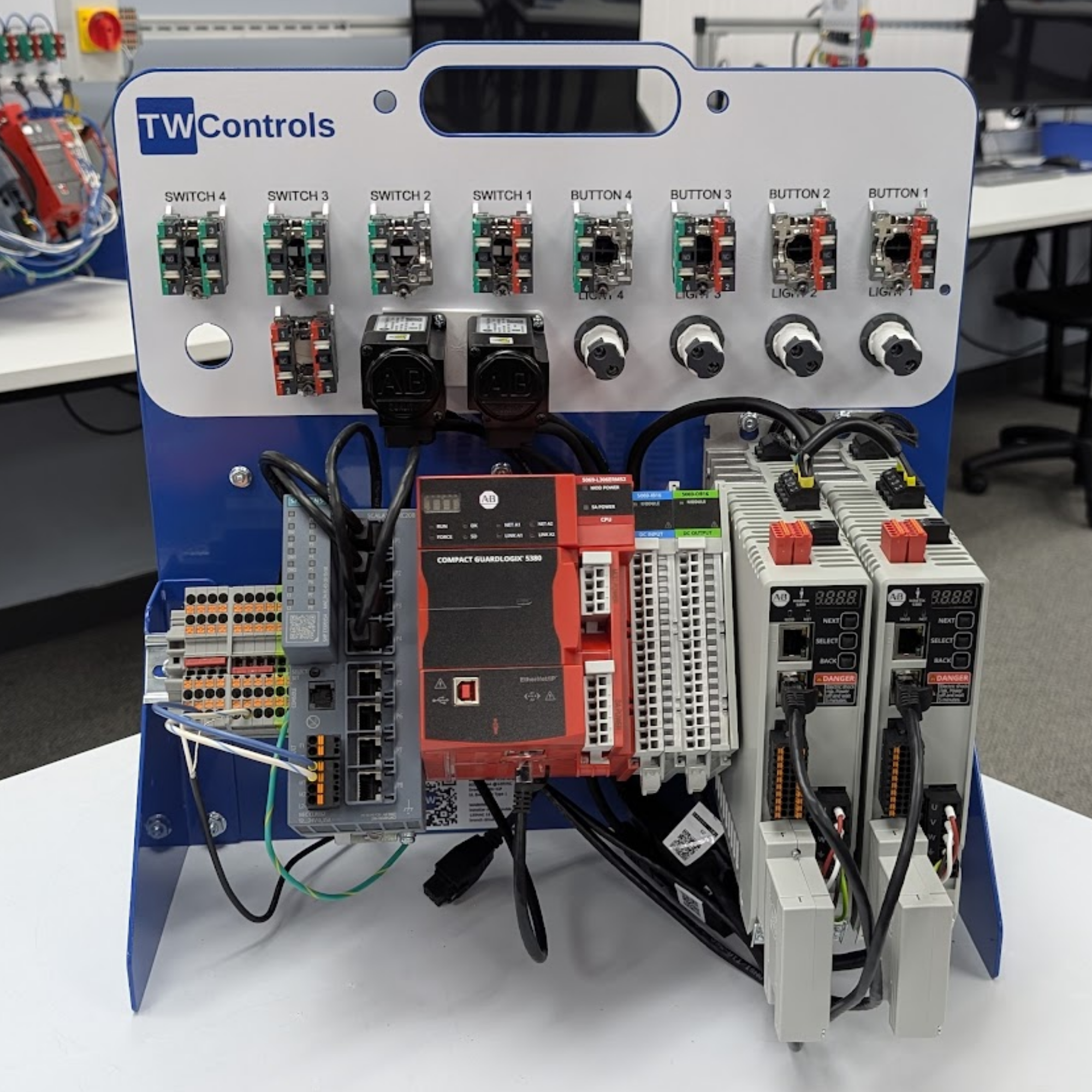

Kinetix Integrated Motion: High-Performance and Coordinated. Kinetix trainers feature Allen-Bradley's dedicated servo drives and motors, integrated with CompactLogix controllers. This is the platform for high-end, complex machinery.

Primary Focus: Programming multi-axis coordinated motion (e.g., electronic gearing, camming) and high-speed, dynamic positioning.

Best for: Engineers and technicians working on robotics, advanced packaging, or any application requiring simultaneous, highly precise movement from multiple axes.

Benefit: Provides deep experience with the industry-standard high-performance servo system, utilizing EtherNet/IP for real-time control and diagnostics.

Customize your PLC Trainer by selecting the brand that you wish to learn and what options you need to accomplish your goals.